UHF RFID Tags Laundry Industry:Garment Tracking and Washing Process

Discover how durable UHF RFID tags are transforming laundry facilities by enhancing inventory tracking, improving efficiency, and streamlining operations.

The heat-sealed textile RFID laundry tag, also known as a RFID laundry tag ,heating adhesive RFID tag or iron RFID fabric tag, is a smart label manufactured through advanced automation technology for textile traceability and inventory management. Using hot melt adhesive (thermal bonding), these labels can be firmly and easily attached to various textiles—whether on the fabric surface or hidden within garment pockets—making them an indispensable tool for industries such as the textile supply chain, hotel linen management, and garment inventory control.

High Mechanical Strength and Durability

Made from a blend of 50% high-quality white cotton and 50% polyester fiber, these washable RFID tags are both flexible and resilient to mechanical wear.

Wide Temperature Range & Heat Resistance

These tags withstand storage temperatures from -40°C to 120°C and endure ironing processes at up to 180°C, making them ideal heat resistant RFID labels for laundry environments.

Long-Lasting Usage

Certified to exceed 200 wash cycles or at least 3 years of use, these labels ensure effective, long-term textile traceability solutions for diverse applications.

Pressure and Chemical Resistance

Able to resist pressures up to 56 bar and withstand common washing chemicals, these tags perform reliably in demanding industrial laundry settings.

Compliance with International RFID Standards

Fully compatible with EPC Class1 Gen2 and ISO18000-6C protocols, the tags work seamlessly with multiple ultra-high-frequency (UHF) RFID readers used worldwide.

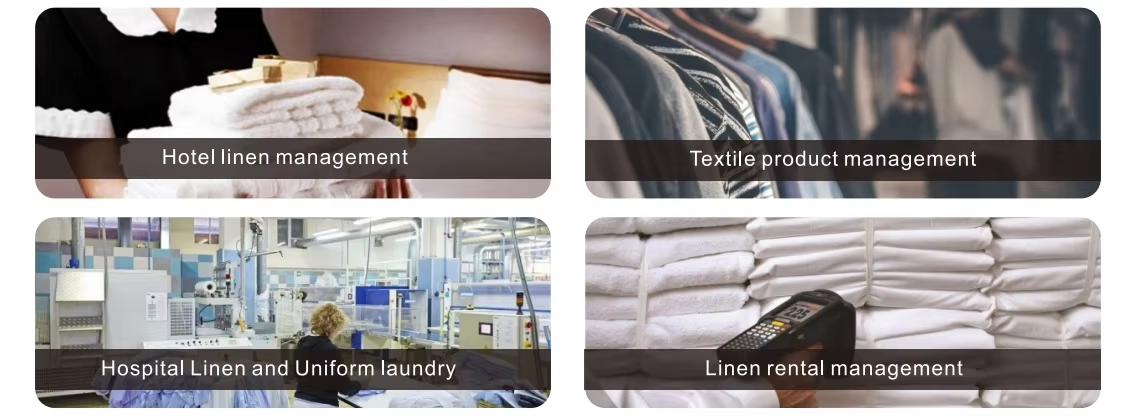

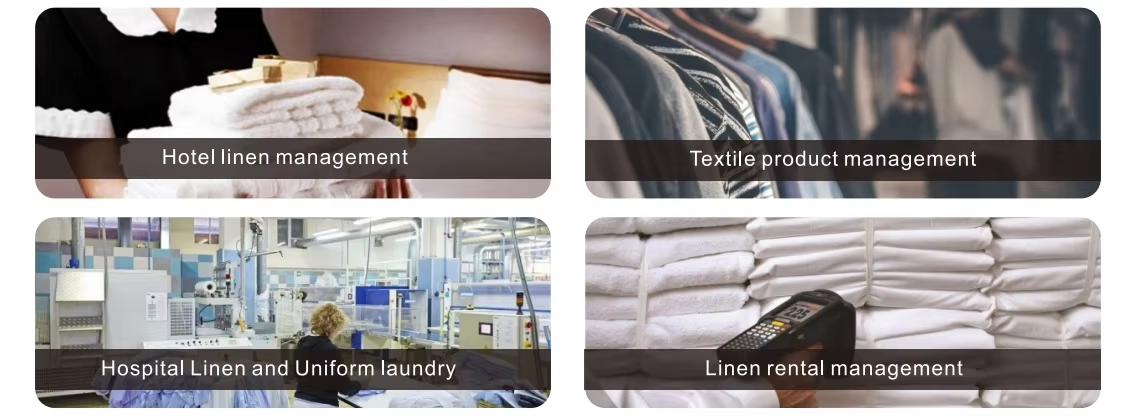

Textile Traceability and Inventory Management

Enable real-time monitoring and quick auditing of fabric inventories to boost transparency and operational efficiency in RFID inventory management.

Hotel Linen RFID Management

Reduce manual errors and extend the usable life of linens through meticulous tracking in hospitality environments.

Supply Chain and Laundry RFID Solutions

Improve supply chain stability and vendor service quality by accurately tracking fabrics from manufacturing to end-use.

Feature | Description |

Material | 50% white polyester + 50% white cotton |

Sizes | 70x15x1mm, 75x15x1mm, 58x15x1mm |

Chip | NXP UCODE 9 |

Operating Temp | -40°C to +120°C |

Ironing Resistance | 180°C for 15 sec, 200 cycles |

Drying Resistance | Up to 150°C, 200 cycles |

Washable Lifespan | 200 cycles or 3 years |

Weight | ~0.90g |

Color | White |

Frequency | 865–928 MHz |

Storage Duration | 10 years |

Q1: How do heat-sealed textile RFID laundry tags withstand high-temperature environments?

A: Thanks to the specially designed hot melt adhesive and rigorous high-temperature testing, these heat resistant RFID labels can endure ironing at 180°C for 15 seconds, repeated up to 200 times, ensuring label stability and readability throughout wash and ironing processes.

Q2: How durable are these RFID laundry tags? How many washes can they withstand?

A: These washable RFID tags are tested to resist over 200 laundering cycles and maintain integrity for a minimum of 3 years under normal usage conditions.

Q3: What types of textiles are these tags suitable for?

A: Constructed from 50% cotton and 50% polyester, the labels provide flexibility and durability. Designed for linen, garments, and various other textiles, they can be discreetly attached without compromising wearer comfort.

Q4: What equipment is required to read data from these hot-stamped RFID tags?

A: Operating at frequencies between 865-928 MHz, these RFID tags require a UHF reader supporting EPC Class1 Gen2 protocol for fast, accurate, and contactless data collection.

Q5: Are these RFID laundry tags waterproof and resistant to chemicals?

A: Yes, they have excellent chemical resistance, withstanding common washing detergents and chemicals, alongside good resistance to water and dust.

Q6: Is the installation process for hot-stamped RFID textile laundry tags complicated?

A: Installation is straightforward and efficient. The hot melt adhesive layer allows quick thermal bonding directly onto textiles, ensuring a strong, durable attachment that enhances production efficiency.

Opting for heat-sealed textile laundry tags or RFID laundry tags means investing in a proven, reliable solution to enhance textile management across industries—whether in hotel linen tracking, garment supply chains, or industrial laundry services. Leverage the power of RFID technology to gain real-time visibility, reduce costs, and enhance operational accuracy today.

Newest trends and common knowledge in RFID laundry tags.

Discover how durable UHF RFID tags are transforming laundry facilities by enhancing inventory tracking, improving efficiency, and streamlining operations.

The NTAG215 RFID NFC Inlays is an excellent choice for various applications requiring smart tagging solutions.

The retail and apparel industries are constantly evolving to meet consumer demands for efficiency, accuracy, and enhanced shopping experiences. One technology driving this transformation is RFID (Radio Frequency Identification). Unlike traditional tags, RFID tags offer real-time data and inventory visibility, streamlining supply chain operations and reducing costs.

As one of the top RFID Tag manufacturers in China, we specialize in high-quality RFID Tag and other RFID products designed to meet the diverse needs of various industries.

@ 2024 RFID Laundry Tag. All right reserved.

Didn’t find what you want? Ask our manager for help!