Optimizing Textile Batch Management with RFID Tag

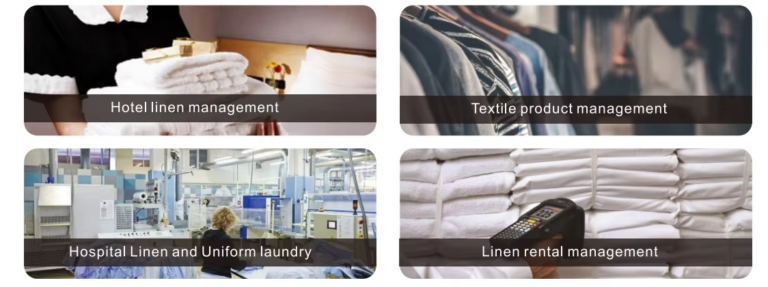

RFID laundry tags are designed specifically for industries where hygiene and inventory control are crucial. These industries include industrial laundries, commercial cleaners, hospitals, etc. High-performance RFID tags solve common challenges in batch laundry tracking, ensuring seamless processes and excellent benefits.

The high durability RFID laundry tags help redefine how healthcare and hotel management textile inventories are managed, providing unmatched efficiency and control.

Traditional garment tracking methods often lead to errors, misplaced items, and low productivity. Say goodbye to manual tracking and welcome automation precision. With the CXJsmart series RFID tags, experience simplified processes, accurate inventory management, and enhanced laundry operation safety.

Which textiles can be tracked using RFID laundry tags? These include hospital and hotel bedsheets, medical clothing and scrub inventory, surgical supplies, uniforms, formal wear, and costumes.

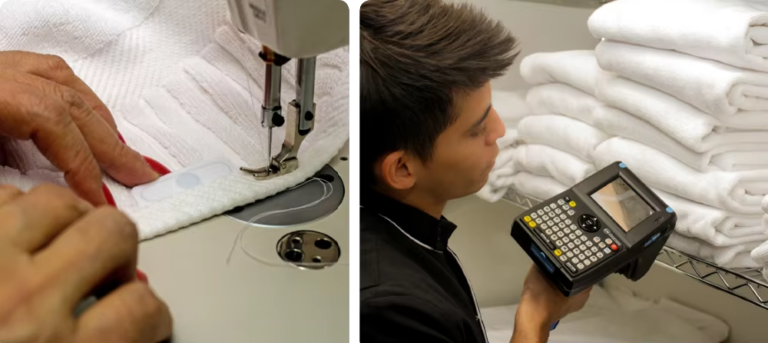

To implement an RFID laundry management system, RFID tags need to be affixed to each garment. This can be accomplished using three standard connection methods, each with its level of durability and tightness:

- Heat Seal – Fastest and most secure. It uses heat and pressure to seal a plastic tag to a textile.

- Stitching – Economically efficient, laundry RFID tags made from fabric are placed on the textile, with stitching at the tag ends (best practice: stitch as close to the tag edge as possible to avoid damaging the antenna).

- Pockets – Securely, RFID tags are inserted into hems, between layers, or into fabric pockets (best practice: ensure the pocket size assists in securing the tag into position).

Can RFID tags withstand industrial laundry processes? Yes, laundry RFID tags, like the CXJsmart series, are meticulously designed to maintain consistent performance even after over 100 standard commercial washing cycles. They are water-resistant, can resist chemicals, including standard detergents, fabric softeners, bleaches, oxygen/chlorine-based substances, alkali, acetic acid, and peracetic acid. They undergo heat cycles at different temperatures and processes, including heat sealing, ironing, drying, steam tunnel, autoclave, and press tunnel washing systems.