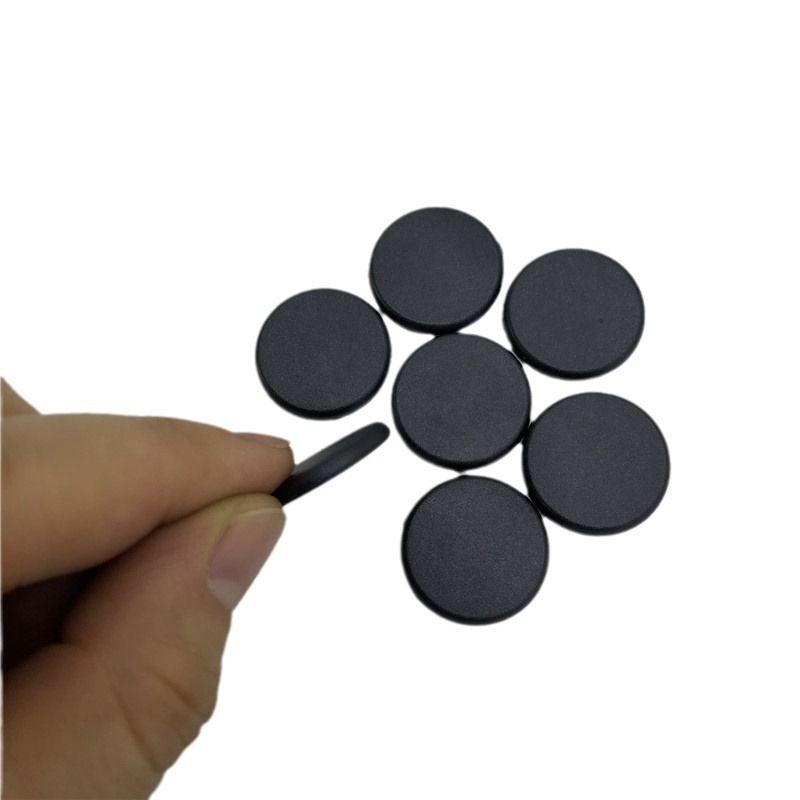

PPS RFID Laundry Tag: Revolutionizing Hospitality Laundry Management

In the fast-paced world of hospitality, where every detail counts towards guest satisfaction, efficient laundry management stands as a pivotal element. From plush towels to crisp bed linens, hotels and resorts strive for excellence in cleanliness and presentation.