What’s 125Khz RFID Laundry Tag?

RFID technology has revolutionized various industries, and in the realm of laundry management, the 125Khz RFID laundry tag stands out as a robust solution for tracking garments and linens through their lifecycle. Designed to endure the rigors of industrial laundering processes, these tags ensure seamless inventory control and enhanced operational efficiency.

Introduction to 125Khz RFID Laundry Tag

In the fast-paced world of laundry management, precision and reliability are paramount. The 125Khz RFID laundry tag represents a pinnacle of innovation, integrating seamlessly into textile rental services, healthcare facilities, and commercial laundries. These tags utilize radio frequency identification (RFID) to transmit data wirelessly, offering real-time tracking and management capabilities that traditional barcode systems cannot match.

Advantages of 125Khz RFID Laundry Tag

Efficiency in Inventory Control: Managing large volumes of textiles requires a system that can keep pace. RFID tags enable quick and accurate inventory counts, reducing human error and streamlining operations.

Durability in Harsh Conditions: Unlike conventional tags, RFID laundry tags are engineered to withstand extreme temperatures, pressures, and chemical exposure, ensuring reliability throughout the laundering process.

Cost-effectiveness in Asset Tracking: By minimizing lost or misplaced items, RFID tags optimize resource allocation and reduce operational costs over time.

Applications of 125Khz RFID Laundry Tag

Textile Rental Industry: In rental services, tracking each garment’s usage and location is crucial. RFID tags automate this process, enabling efficient stock replenishment and maintenance scheduling.

Laundry Service Providers: Commercial laundries benefit from RFID’s ability to handle high-throughput environments, enhancing sorting accuracy and delivery timelines.

Healthcare Sector: Hospitals rely on RFID to manage linen inventory and hygiene compliance, ensuring patient safety and operational efficiency.

Technical Specifications of 125Khz RFID Laundry Tag

RFID Frequency and Technology: Operating at 125Khz, these tags utilize low-frequency signals for reliable communication across various textile materials.

Heat and Chemical Resistance: Encapsulated in flexible textiles, RFID tags withstand temperatures encountered in industrial drying and ironing processes, maintaining data integrity.

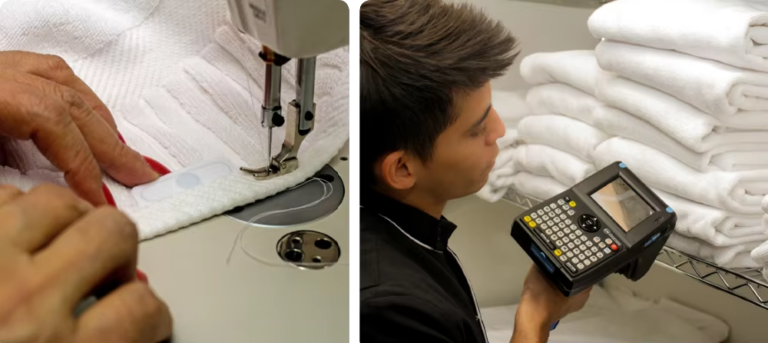

Integration with Laundry Processes: Compatible with heat sealing machines, RFID tags seamlessly adhere to fabrics without compromising comfort or durability.

Design and Construction of RFID Laundry Tags

Components of the Tag: Each tag contains a tiny chip module and an antenna, encased in durable materials that shield them from physical and environmental damage.

Encapsulation Techniques: Specialized coatings protect internal components from moisture, detergents, and mechanical stress, ensuring prolonged lifespan and performance.

Compatibility with Fabric Materials: From delicate linens to heavy-duty uniforms, RFID tags are designed to adhere securely to various textiles without affecting comfort or appearance.

Benefits of Using 125Khz RFID Tags in Laundry Operations

Improved Efficiency and Accuracy: Automated data capture reduces human error and speeds up processes, allowing staff to focus on value-added tasks.

Reduction in Loss and Theft: Real-time tracking deters theft and loss, minimizing replacement costs and ensuring continuous availability of inventory.

Enhanced Customer Satisfaction: Prompt service and accurate order fulfillment enhance customer experience, fostering loyalty and repeat business.

Challenges and Solutions in Implementing RFID in Laundry Management

Initial Setup and Integration: Adopting RFID requires upfront investment in infrastructure and staff training, but the long-term benefits outweigh initial costs.

Maintenance and Tag Replacement: Regular maintenance schedules and quality control measures mitigate risks of tag failure and ensure uninterrupted service.

Training and Adoption Issues: Educating staff on RFID’s benefits and operational procedures promotes acceptance and maximizes system utilization.

Case Studies: Successful Implementations of 125Khz RFID Tags

Case Study 1: Textile Rental Company A: By implementing RFID, Company A reduced inventory discrepancies by 30% and improved delivery accuracy, enhancing customer satisfaction.

Case Study 2: Hospital Laundry Services: RFID tags enabled Hospital X to track linen usage in real time, optimizing inventory levels and ensuring compliance with hygiene standards.

Comparison with Other RFID Technologies

High Frequency (HF) RFID Tags: Suitable for shorter-range applications, HF RFID tags offer higher data transfer rates but may be less resilient in harsh environments.

Ultra High Frequency (UHF) RFID Tags: Ideal for long-range tracking, UHF RFID tags excel in logistics and supply chain management but may require larger tag sizes for textile applications.

Future Trends in RFID Technology for Laundry Management

Innovations in RFID Tag Design: Advancements in miniaturization and material sciences will further enhance tag durability and performance in diverse laundry settings.

IoT Integration in Laundry Systems: Integration with Internet of Things (IoT) platforms will enable predictive maintenance and enhanced data analytics, optimizing resource allocation.

Environmental Impact and Sustainability of RFID Tags

Recycling and Disposal Considerations: RFID tags are recyclable, and responsible disposal practices minimize environmental footprint, aligning with sustainability goals.

Energy Efficiency in Laundry Operations: By reducing manual handling and optimizing workflows, RFID technology lowers energy consumption and enhances operational efficiency.

Regulatory Compliance and Standards for RFID in Textile Industries

FDA and Other Regulatory Guidelines: Compliance with FDA regulations ensures RFID tags used in healthcare settings meet safety and performance standards, promoting patient welfare.

Industry Standards and Certifications: Adherence to ISO standards guarantees tag interoperability and data security, fostering trust among stakeholders in the supply chain.

Cost Analysis and Return on Investment (ROI)

Initial Costs vs. Long-term Savings: While initial setup costs may be significant, the ROI from improved efficiency and reduced operational losses justifies the investment.

ROI Calculation Examples: Calculating ROI based on reduced labor costs, inventory accuracy improvements, and extended tag lifespan demonstrates the financial benefits of RFID adoption.

Conclusion

The 125Khz RFID laundry tag is not just a technological advancement; it’s a cornerstone of efficiency and reliability in laundry management. From textile rentals to healthcare facilities, its robust design and seamless integration capabilities redefine how we manage and track textiles. As the industry evolves, RFID technology will continue to play a pivotal role in enhancing operational efficiency and customer satisfaction.

FAQs about 125Khz RFID Laundry Tags

- What are RFID laundry tags used for? RFID laundry tags are used for tracking garments and textiles throughout their lifecycle, from laundry facilities to end-users.

- How do RFID laundry tags withstand high temperatures? Encapsulated in heat-resistant materials, RFID tags endure industrial drying and ironing processes without compromising functionality.

- Can RFID tags be reused after laundry cycles? Yes, RFID tags are designed for multiple use cycles, maintaining performance and data integrity over extended periods.

- Are RFID laundry tags waterproof? While not waterproof, RFID laundry tags are resistant to moisture and common laundering chemicals, ensuring durability.

- What are the security measures for RFID laundry tags? RFID tags employ encryption and unique identifiers to prevent unauthorized access and ensure data security throughout operations.

This comprehensive guide showcases the transformative impact of 125Khz RFID laundry tags, highlighting their versatility, durability, and potential across various industries. Whether optimizing inventory management or enhancing customer satisfaction, RFID technology continues to redefine efficiency in laundry operations.