Understanding RFID Tags: Frequency Ranges and Practical Applications

RFID tags are wireless devices featuring microchips and antennas, used for tracking and managing items in logistics, retail, healthcare, and more.

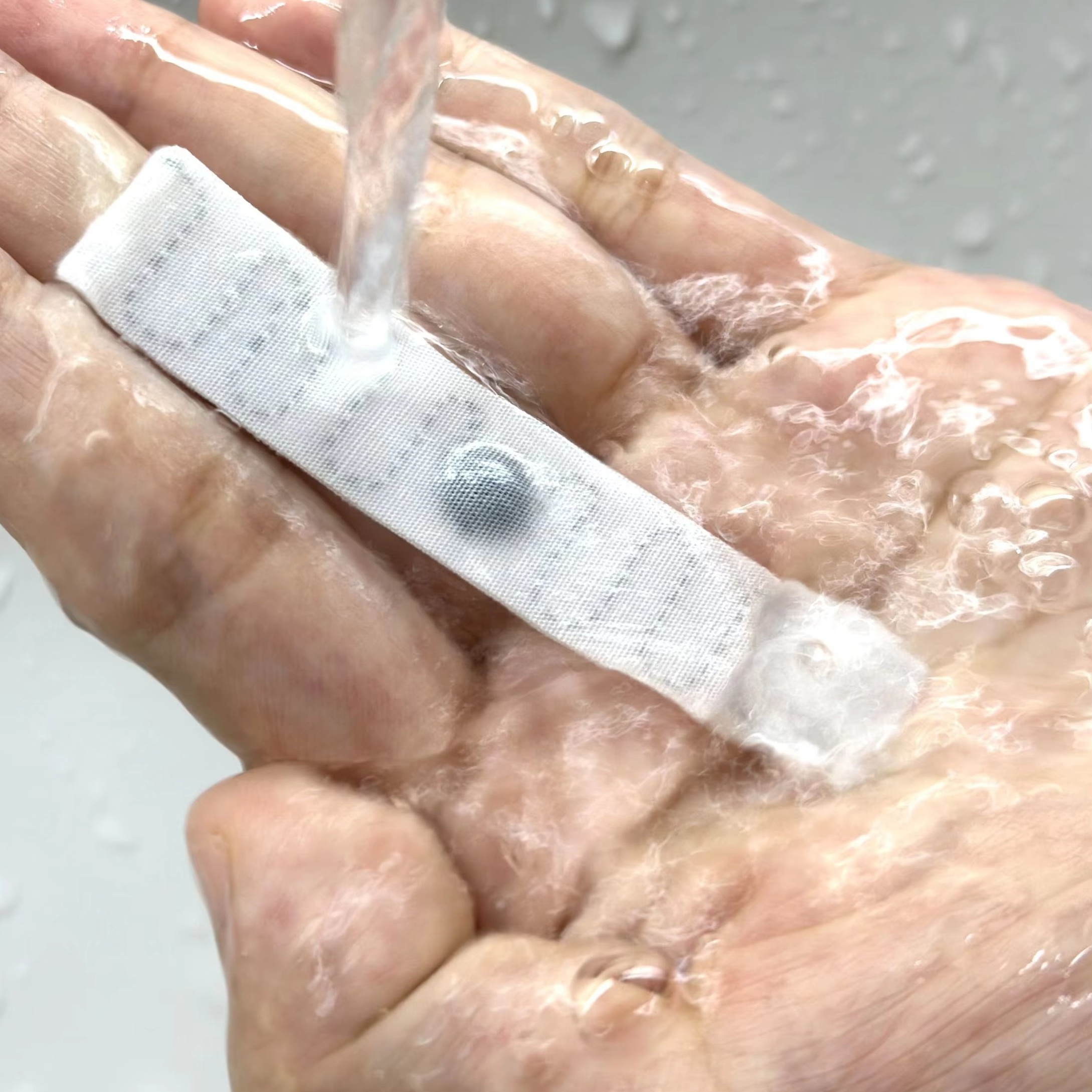

The UHF RFID Laundry Tag, utilizing the NXP UCODE 9 chip, represents a groundbreaking advancement in the automation of sorting and inventory management in laundry applications. This technology combines enhanced sensitivity and versatile memory configurations, delivering superior performance and reliability in tracking textiles and garments. The UCODE 9 chip boasts a sensitivity that is more than three times that of its predecessors, facilitating the use of smaller tag antennas and enabling the tagging of a broader range of objects. This heightened sensitivity is crucial in ensuring dependable tag readings in environments like laundries where efficient and accurate inventory management is essential. The NXP UCODE 9 chip offers 880 bits of memory, configurable between EPC (Electronic Product Code) and user memory banks, allowing for detailed data storage such as lot numbers, production dates, and process parameters. The chip also incorporates robust data protection features, including Error Correction Code (ECC) and BlockPermalock functionality, which secure data integrity and prevent unauthorized alterations. This level of data security is vital for maintaining the accuracy and reliability of inventory systems. In practical applications, UHF RFID Laundry Tags streamline and automate several processes, from sorting and counting to record-keeping, thereby significantly reducing labor costs and improving operational efficiency. The tags provide complete visibility into linen inventory and customer transactions, enabling real-time monitoring and control. This not only optimizes inventory movement but also aids in compliance with hygiene norms by reducing physical contact with textiles. Additionally, the integration of RFID data into cloud-based platforms like HID’s Acuity enhances transparency and operational oversight, further contributing to efficiency and cost savings. Despite its numerous benefits, the implementation of UHF RFID technology in laundry management is not without challenges. Issues such as interference from other radio transmissions, the lack of standardization across different regions, and privacy concerns related to unauthorized access to RFID data pose significant obstacles. Addressing these challenges requires a coordinated approach involving technological advancements, industry-wide standardization, and robust security measures. As the technology continues to evolve, UHF RFID Laundry Tags are poised to play a pivotal role in transforming inventory management and operational processes in the laundry industry and beyond.

The UHF RFID Laundry Tag, incorporating the advanced NXP UCODE 9 chip, represents a significant technological leap in the field of automatic sorting and checking systems for laundry applications. This technology combines high sensitivity and configurable memory options, which enhances the overall system performance and reliability, providing a comprehensive solution for inventory management and tracking. UCODE 9xm delivers industry-leading performance by offering more than three times the sensitivity of its predecessors, allowing for smaller tag antennas and enabling the tagging of a wider variety of objects. This high level of sensitivity is critical in environments where reliable tag reading is necessary, such as in the management of textiles and garments in the laundry industry. The chip features 880 bits of total memory, which is shared between the EPC (Electronic Product Code) and user memory banks. Users can configure the memory to meet specific needs, with up to 496 bits available for EPC memory and up to 752 bits for user memory. This flexibility allows for the storage of detailed manufacturing data, including lot numbers, production dates, and process parameters. Such capabilities are essential for comprehensive inventory and supply chain management. Furthermore, the UCODE 9xm is equipped with robust data protection features, including an Error Correction Code (ECC) algorithm and parity checks, which safeguard the integrity of the stored data. Integrated BlockPermalock functionality allows certain sections of data to be protected from changes while permitting updates to other sections. Additionally, independent access and kill passwords enhance security by preventing unauthorized access and tampering. The implementation of this RFID technology in laundry applications facilitates real-time and efficient inventory management, allowing for quick monitoring of stock levels. It also aids in production monitoring and control by detecting the location and movement of components, semi-finished, and finished products. This contributes to improved productivity and quality control in the production environment.

UHF RFID Laundry Tags have revolutionized the sorting and checking processes in various industries by providing a comprehensive solution for managing large volumes of linen efficiently. These tags enable retail environments to monitor and control floor-level out-of-stocks (OOS), particularly in areas with high product display density and low staffing levels, where the risk of mishandling is high. The stock levels of items can be accurately maintained, allowing for items to be grouped according to demand. Additionally, RFID technology ensures the accuracy of deliveries quickly with less labor, improving inventory accuracy and enabling automatic replenishment of stock. In laundry management, RFID tags offer complete visibility into linen inventory and customer transactions, generating transparency and optimizing inventory movement. HID’s Acuity platform, a digital solution for laundry management, transforms RFID data into interactive, cloud-based dashboards and reports that provide real-time overviews of linen inventory by item reference, zone, and customer. This platform significantly reduces operating costs by decreasing the number of staff required for receiving laundry, thus improving efficiency and accuracy. Using RFID technology in the laundry industry also simplifies and automates several processes. For example, the automatic counting of several hundred items in a few seconds has led to a reduction in labor costs, eliminating the need for manual sorting, counting, and record-keeping. The technology also helps in maintaining hygiene norms and sanitary guidelines by reducing physical contact with textile items, thereby creating a safer working environment. Furthermore, RFID tags are instrumental in recording essential details such as unit-of-use serial numbers, country of origin, and the concentration of specific chemicals. These tags can store crucial data, such as lot numbers and expiration dates, which can be accessed even when a cloud connection isn’t available. This feature ensures that downstream partners receive the right data at the right time, improving supply-chain management and inventory tracking.

RFID technology has a multitude of applications in various processes involved in the fashion supply chain, addressing a range of unique challenges specific to the industry. The fashion supply chain can be divided into four main sectors: manufacturing, overseas transportation, distribution, and retailing.

In the manufacturing sector, RFID can be utilized to avoid the mixing of products and components, as well as different accessories, thereby ensuring that the right components are used in the production process. Additionally, RFID enables real-time monitoring of stock levels inside the production department, facilitating efficient inventory management. The location and movement of components, semi-finished, and finished products can be detected, aiding in production monitoring and control.

Implementing UHF RFID systems in laundry operations significantly reduces operational costs by eliminating labor-intensive tasks such as manual sorting, counting, and recordkeeping. The use of portable handheld RFID readers with mobile software minimizes the need for physical contact, ensuring a safer working environment in compliance with hygiene norms. Such systems can reduce non-theft related losses by 100% and cut labor costs by 50%.

UHF RFID technology enables various automated processes in laundry operations, such as automatic sorting and real-time item tracking. Items tagged with UHF RFID can be sorted based on encoded part numbers, which has already been successfully implemented. This method is cost-effective and does not affect the appearance of the items. However, options such as sewing on tags with pouches or textile labels are more expensive but offer added value through branding.

RFID laundry tags into waterproof, heat-resistant, and ordinary types, depending on their intended use environment. Waterproof laundry tags are constructed from high-density polyethylene (HDPE) or other waterproof materials, providing excellent waterproof performance even after repeated washes. Heat-resistant tags, on the other hand, use special materials like high-temperature nylon or heat-resistant silicone. These tags are rigorously tested to maintain stable performance under high-temperature steam, industrial detergents, and mechanical pressure, ensuring accurate tracking during industrial washing processes.

Newest trends and common knowledge in RFID laundry tags.

RFID tags are wireless devices featuring microchips and antennas, used for tracking and managing items in logistics, retail, healthcare, and more.

RFID keyfobs are small, contactless devices using radio-frequency tech for secure access. The Mifare S50 1K operates at 13.56 MHz for reliable, efficient control.

Laundry RFID Wash Care Labels offer a unique blend of traditional garment care information with advanced RFID technology.

Didn’t find what you want? Ask our manager for help!