Silicone RFID Laundry Tags in Industrial Laundry Operations

Introduction

RFID silicone tags represent a technological advancement in durable tracking solutions for various industries. These tags are characterized by their slim size, flexibility, soft texture, and smooth surface. They are designed to withstand exposure to chemicals and liquids, making them ideal for environments requiring stringent hygiene standards. Moreover, these tags exhibit heat and strength resistance, ensuring durability under harsh conditions such as industrial laundering processes. Embedded with robust RFID transponders, they can endure up to 200 cycles of drum washing, heat drying, cleaning, and ironing without compromising performance or readability.Durable for 200 Washing, Drying, Cleaning, and Ironing Cycles:

- Extreme Temperature Resistance: Silicone RFID tags are engineered to withstand high temperatures, including sterilization processes up to +121°C (250°F) for 15 minutes. This makes them suitable for medical applications and high-heat laundry cycles.

- Mechanical Strength: The silicone material is flexible yet robust, capable of withstanding the repeated stresses of washing, drying, cleaning, and ironing without cracking or breaking. This ensures the tag remains securely attached to the laundry item throughout its lifecycle.

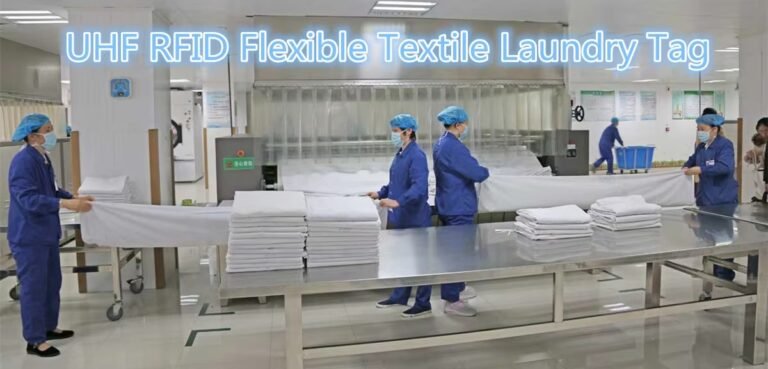

Silicone RFID laundry tags are revolutionizing industrial laundry operations by offering a robust solution to manage large volumes of workwear, uniforms, towels, and other items efficiently. Here’s a breakdown of how they are making a significant impact:

Boosting Efficiency and Accuracy:

- Real-time Inventory Tracking: RFID tags provide continuous monitoring of laundry items throughout the entire process, from receiving dirty laundry to delivering clean items.

- Automated Sorting and Distribution: RFID readers can automatically sort and direct laundry items to specific locations based on their individual tags, eliminating manual sorting and reducing human error.

- Accurate Item Counting: RFID tags eliminate the need for manual counting, ensuring precise inventory management and minimizing losses due to misplaced or missing items.

Optimizing Processes and Reducing Costs:

- Streamlined Workflows: Automated processes reduce the time and labor required for sorting, washing, drying, and distribution, leading to faster turnaround times.

- Reduced Labor Costs: Automation eliminates the need for manual handling, significantly reducing labor costs and freeing up staff for other tasks.

- Minimized Laundry Losses: Accurate tracking prevents losses due to misplaced items or accidental disposal, reducing overall laundry costs.

Enhancing Sustainability and Safety:

- Optimized Laundry Cycles: By tracking individual items, RFID tags allow for proper wash cycle customization, preventing over-laundering and reducing energy and water consumption.

- Improved Hygiene and Safety: RFID tags can be used to track the cleaning and disinfection history of linens and workwear, ensuring proper hygiene standards and reducing the risk of cross-contamination.

- Reduced Waste: Tracking and inventory management helps prevent unnecessary replacements, reducing textile waste and promoting a more sustainable approach.

Beyond the Basics:

- Detailed Usage Data: RFID tags can collect data on the usage frequency and wear-and-tear of individual items, enabling better inventory planning and reducing unnecessary replacements.

- Employee Tracking: RFID tags can be integrated with time and attendance systems, providing accurate tracking of employee work hours and ensuring proper workwear usage.

Overall:

Silicone RFID laundry tags are a game changer for industrial laundry operations, offering a comprehensive solution for tracking, managing, and optimizing laundry processes. They enhance efficiency, reduce costs, improve sustainability, and contribute to a safer and more hygienic environment. As RFID technology continues to evolve, we can expect even more innovative applications to emerge, further transforming industrial laundry practices.