Ultimate Guide to RFID Keyfobs: Understanding Mifare S50 1K Technology in 2024

RFID keyfobs are small, contactless devices using radio-frequency tech for secure access. The Mifare S50 1K operates at 13.56 MHz for reliable, efficient control.

Practical Solutions for Large-Scale Textile Management

Managing textiles at scale is one of the least visible yet most operationally demanding challenges in industries such as healthcare, hospitality, and industrial manufacturing. Hospitals process thousands of gowns and linens daily. Hotels must ensure clean, available textiles without overstocking. Commercial laundries handle garments from multiple clients under strict turnaround and accountability requirements.

Traditional tracking methods—manual counting, barcode labels, handwritten logs—struggle to keep up with this complexity. Errors accumulate quietly: missing items, inaccurate inventory, unnecessary replacements, and rising labor costs.

RFID tags for industrial laundry address these issues at the system level, not by adding more labor, but by making textiles digitally traceable throughout their entire lifecycle.

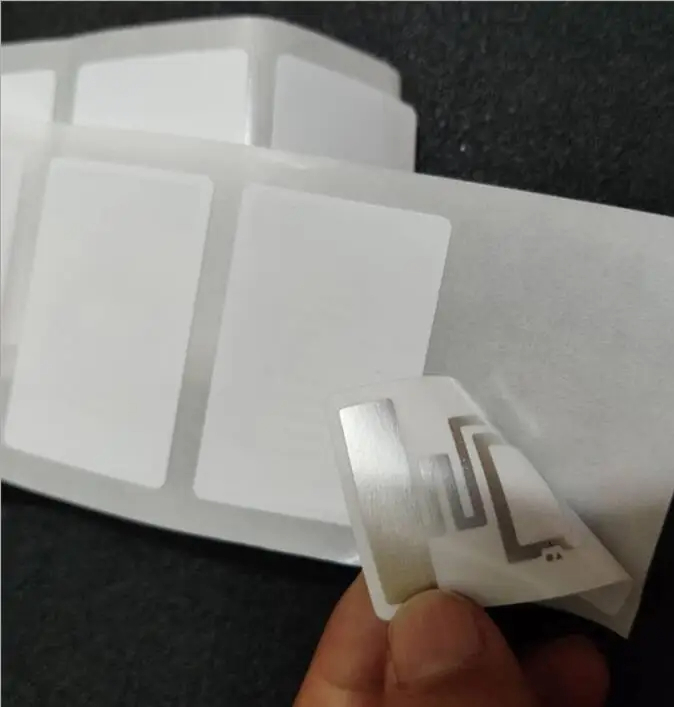

RFID laundry tags—often referred to as RFID linen chips—are compact, durable RFID transponders designed specifically for harsh laundry environments. Each tag contains a microchip and antenna that transmits a unique identifier to RFID readers via radio frequency.

These tags are embedded into textiles by sewing, heat sealing, or pouch insertion and are engineered to withstand:

Repeated industrial washing and drying

High temperatures and pressure

Chemical detergents and disinfectants

Mechanical stress during sorting and transport

Unlike barcodes, RFID tags do not require line-of-sight scanning. Hundreds of tagged items can be identified simultaneously, even when stacked, bundled, or placed inside laundry bags.

As labor costs rise and service-level expectations increase, laundry operations are under pressure to become more automated, transparent, and data-driven. RFID technology directly supports these objectives.

Manual counting and sorting are time-consuming and error-prone. RFID automates these tasks, allowing staff to focus on quality control and exception handling rather than repetitive labor.

RFID provides continuous insight into how many items exist, where they are, and what stage of the laundry process they are in—eliminating guesswork and reconciliation delays.

By tracking each item individually, RFID makes losses measurable and traceable. Missing items can be identified by last known location, reducing disputes between laundries and clients.

RFID data records wash counts and usage frequency. This enables operators to retire linens based on actual wear instead of estimates, extending usable life while maintaining quality standards.

Over time, RFID systems generate reliable datasets that reveal bottlenecks, overstock patterns, and inefficiencies—supporting continuous improvement and cost control.

RFID integrates seamlessly into existing laundry processes without disrupting daily operations.

Tagging

Each textile item is fitted with a washable RFID tag, assigned a unique ID.

Registration

The tag ID is linked in the system to item attributes such as type, size, customer, department, or ownership.

Automated Reading

RFID readers installed at collection points, wash lines, dryers, sorting stations, and dispatch areas automatically capture tag data as items move through the facility.

Sorting and Processing

Items can be automatically sorted by client, garment type, or priority without manual checking.

Inventory and Reporting

The system updates inventory levels in real time, providing accurate counts and historical usage data.

Loss Analysis and Accountability

Missing items can be traced to specific process stages, reducing disputes and improving accountability.

Hospitals use RFID to manage patient gowns, surgical textiles, and staff uniforms. This reduces loss, improves hygiene compliance, and ensures critical items are always available.

Hotels rely on RFID to balance linen availability with storage costs, minimize shrinkage, and maintain consistent guest experience across properties.

RFID enables precise tracking of employee uniforms and protective garments, supporting compliance, safety audits, and controlled distribution.

Multi-client laundries use RFID to separate customer inventory, provide transparent reporting, and improve service accuracy.

Not all RFID tags are suitable for industrial laundry. Poor-quality tags fail prematurely, leading to data gaps and replacement costs.

Our RFID laundry tags are designed specifically for long-term deployment in demanding conditions, offering:

High resistance to heat, chemicals, and mechanical stress

Stable read performance across hundreds of wash cycles

Flexible attachment options for different fabric types

Compatibility with UHF or HF laundry RFID systems

Equally important, we support customers beyond hardware—assisting with tag selection, system integration, and operational best practices.

When implemented correctly, RFID is not just a tracking tool but a foundation for digital laundry management. It transforms textiles from anonymous consumables into traceable assets with measurable performance.

This shift enables better purchasing decisions, fair client billing, and predictable operational costs—critical advantages in highly competitive laundry markets.

RFID tags for industrial laundry offer a practical, proven solution to the challenges of large-scale textile management. By replacing manual processes with automated identification and real-time data, organizations gain control, transparency, and efficiency across the entire laundry lifecycle.

For hospitals, hotels, manufacturers, and commercial laundries, RFID is no longer an experimental technology—it is an operational necessity for sustainable, scalable growth.

Newest trends and common knowledge in RFID laundry tags.

RFID keyfobs are small, contactless devices using radio-frequency tech for secure access. The Mifare S50 1K operates at 13.56 MHz for reliable, efficient control.

In today’s fast-paced world, technology is continuously evolving, enhancing convenience and efficiency in our daily lives. RFID tag utilizes electromagnetic fields to automatically identify and track tags attached to objects.

Revolutionize uniform management in healthcare with RFID technology. Smart cabinets and room-based systems streamline operations, cutting costs and enhancing efficiency.

Didn’t find what you want? Ask our manager for help!