RFID Cable Tie Tags

RFID Cable Tie Tags offer an innovative solution that combines the robustness of traditional cable ties with the advanced capabilities of RFID technology.

FID Cable Tie Tags: Revolutionizing Product Identification and Management

RFID Cable Tie Tags offer an innovative solution that combines the robustness of traditional cable ties with the advanced capabilities of RFID technology. These tags facilitate clear and rapid product identification, enhancing processes in areas such as resource management, electrical inspection, inventory, distribution, rental services, and maintenance. This comprehensive guide delves into the features, benefits, and applications of RFID Cable Tie Tags, illustrating why they are an essential tool for modern businesses.

What is an RFID Cable Tie Tag?

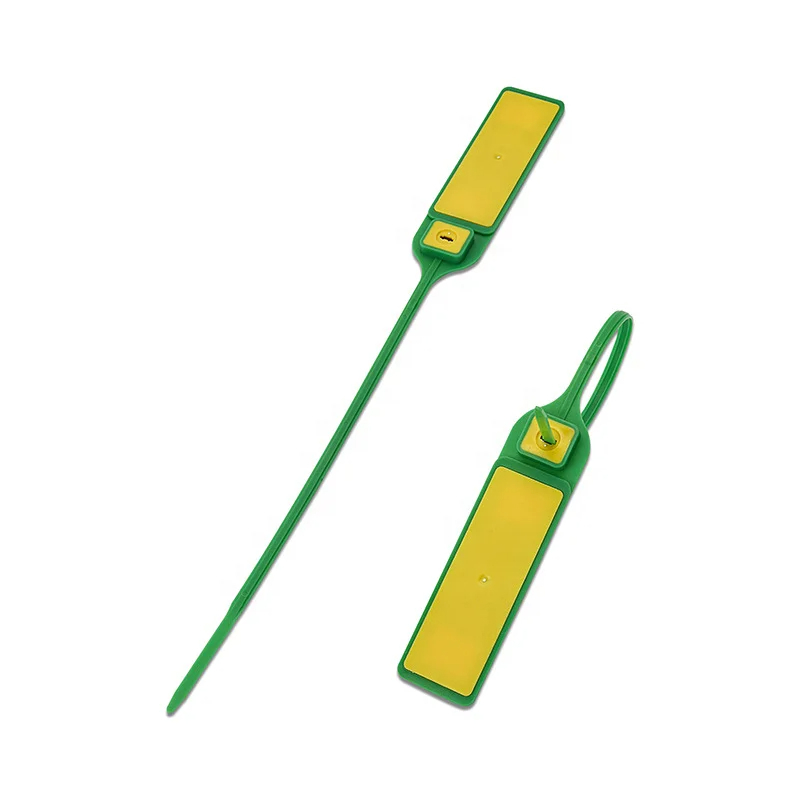

An RFID Cable Tie Tag is a versatile tool that merges the functionality of a traditional cable tie with RFID (Radio Frequency Identification) technology. These cable ties are equipped with an RFID transponder, allowing for wireless data communication and enabling features such as tracking, serialization, and product identification. Unlike conventional cable ties that require cutting to be removed or adjusted, releasable ties can be easily removed and reused, promoting sustainability and reducing waste.

RFID Cable Tie Tags are particularly suited for applications in resource management, electrical inspection, inventory control, distribution, rental services, and maintenance routines. By embedding RFID technology into nylon cable ties, businesses can streamline their operations, enhance accuracy, and improve overall efficiency.

Key Features of RFID Cable Tie Tags

1. Flexible, Contactless Data Communication

One of the standout features of RFID Cable Tie Tags is their ability to facilitate contactless data communication. UHF(800mhz~960mhz), HF(13.56MHZ), HF with reading distance of 1-5cm, UHF is 0.1-2m, these tags enable wireless data transfer between the tag and RFID readers without the need for physical contact.

- Seamless Integration: Easily integrates with existing RFID systems, allowing for quick adoption and minimal disruption.

- Enhanced Accessibility: Enables swift access to data, improving response times in critical operations.

2. Clear Identification of Objects Through Unique Numbering

Each RFID Cable Tie Tag is embedded with a unique identifier, ensuring precise product identification and serialization. This unique numbering system eliminates the ambiguity often associated with manual labeling.

- Unique ID Numbers: Assigns distinct ID numbers to each tag, facilitating accurate tracking and management.

- Preventing Duplicates: Ensures that each item is uniquely identifiable, reducing errors in inventory systems.

3. Faster Data Management Compared to Paper Solutions

Traditional paper-based labeling systems are prone to delays and errors. RFID Cable Tie Tags offer a significant improvement by enabling rapid data access and management.

- Instant Data Retrieval: Quickly access information stored on the tags, enhancing operational efficiency.

- Real-Time Updates: Facilitate instantaneous updates to databases, ensuring that information is always current.

4. More Accurate Documentation Processes – Prevention of Human Errors

Manual data entry is susceptible to human errors, which can lead to significant issues in inventory and asset management. RFID Cable Tie Tags automate the documentation process, ensuring higher accuracy.

- Automated Tracking: Reduces the need for manual entry, minimizing the risk of errors.

- Consistent Data Logging: Ensures uniformity in data records, enhancing reliability.

5. Robust and Resistant to Harsh Environments and Cleaning Processes

Designed to withstand tough conditions, RFID Cable Tie Tags are robust and durable, making them suitable for various industrial environments.

- Durable Materials: Made from nylon and other resilient materials, ensuring longevity.

- Environmental Resistance: Resistant to moisture, chemicals, and extreme temperatures, maintaining functionality in harsh settings.

6. Low Frequency (LF – 125 kHz) – Read Only

LF RFID Cable Tie Tags operate at a lower frequency, making them ideal for applications requiring simple, read-only data access.

- Simplified Use: Perfect for straightforward tracking and identification tasks.

- Cost-Effective: Typically more affordable due to their read-only nature.

7. High Frequency (HF – 13.56 MHz) – Rewritable

HF RFID Cable Tie Tags offer rewritable capabilities, allowing for dynamic data storage and updates.

- Flexible Data Management: Easily update information stored on the tags as needed.

- Enhanced Functionality: Suitable for applications requiring frequent data changes and updates.

8. Certifications & Approvals

Our RFID Cable Tie Tags adhere to international standards, ensuring compatibility and reliability across various systems and applications.

- ISO Compliance: Meets ISO/IEC 18000 standards for RFID technology.

- Quality Assurance: Rigorous testing to ensure performance and durability.

Benefits of Using RFID Cable Tie Tags

Enhanced Efficiency in Production

Integrating RFID Cable Tie Tags into your production processes significantly enhances efficiency. By combining fastening, bundling, labeling, identification, and tracking into a single step, these tags eliminate multiple processes, saving time and reducing labor costs.

- Streamlined Operations: Consolidates multiple tasks into one, reducing process complexity.

- Increased Throughput: Accelerates production cycles by minimizing manual interventions.

Reliable Labeling and Identification in Harsh Environments

Traditional labels and tags can degrade or become unreadable in harsh environments. RFID Cable Tie Tags are designed to remain functional even under extreme conditions, ensuring that RFID technology remains reliable.

- Weatherproof Design: Maintains readability in outdoor and industrial settings.

- Chemical Resistance: Withstands exposure to various chemicals without losing functionality.

Marking and Identifying Inaccessible Parts

Certain parts of equipment or products are difficult to label using conventional methods. RFID Cable Tie Tags offer a reliable alternative, enabling the marking and identification of these inaccessible areas.

- Flexible Placement: Can be attached to hard-to-reach areas without compromising performance.

- Consistent Identification: Ensures that every part is uniquely identifiable, regardless of accessibility.

Sustainable and Cost-Effective Solution

By utilizing releasable ties, businesses can reuse RFID Cable Tie Tags multiple times, reducing waste and promoting sustainability. This reuse capability not only benefits the environment but also results in cost savings over time.

- Eco-Friendly: Minimizes waste by allowing tags to be reused.

- Long-Term Savings: Reduces the need for frequent replacements, lowering overall costs.

Technical Specifications

Understanding the technical specifications of RFID Cable Tie Tags is crucial for selecting the right product for your needs. Below is a detailed overview of our tags’ capabilities:

| Specification | Details |

|---|---|

| Material | Nylon, ABS, and other durable materials |

| Frequency | LF – 125 kHz / HF – 13.56 MHz/UHF-860~960MHz |

| Operating Distance | Up to 100 mm depending on the reader |

| Memory Capacity | Varies based on tag type (read-only or rewritable) |

| Dimensions | 200×4.6mm |

| Weather Resistance | Waterproof, resistant to harsh environments |

| Security Features | Encryption, authentication via ECC |

| Compliance | ISO/IEC 18000 standards |

| Packaging | Available in bulk and individual packaging |

| Warranty | 1-year manufacturer warranty |

Chip Types and Memory

Our RFID Cable Tie Tags are equipped with advanced chips to ensure optimal performance:

- NTAG213: 144 bytes of user memory, ideal for basic identification tasks.

- NTAG215: 504 bytes of user memory, suitable for more extensive data storage.

- NTAG216: 888 bytes of user memory, perfect for complex applications requiring substantial data capacity.

- Higgs™ 9: 96-bit expandable EPC,688 bit user memory

Applications Across Various Industries

RFID Cable Tie Tags are incredibly versatile, finding applications across multiple industries. Here are some of the key sectors benefiting from this technology:

1. Resource Management

Efficient resource management is critical in any organization. RFID Cable Tie Tags streamline the tracking and allocation of resources, ensuring that assets are utilized optimally.

- Asset Tracking: Easily monitor the location and status of equipment and materials.

- Inventory Control: Maintain accurate inventory levels, reducing the risk of overstocking or stockouts.

2. Electrical Inspection

In electrical inspection, safety and accuracy are paramount. RFID Cable Tie Tags provide a reliable method for labeling and tracking electrical components.

- Component Identification: Quickly identify and locate specific electrical parts.

- Safety Compliance: Ensure that all components are correctly labeled for safety inspections.

3. Inventory and Distribution

Managing inventory and distribution efficiently can significantly impact a company’s bottom line. RFID Cable Tie Tags enhance these processes by providing real-time tracking and management capabilities.

- Real-Time Tracking: Monitor inventory levels and movement in real-time, improving accuracy.

- Streamlined Distribution: Optimize distribution routes and reduce delays with accurate tracking data.

4. Rental Services

For rental services, keeping track of assets is essential. RFID Cable Tie Tags simplify asset management, ensuring that all rented items are accounted for and maintained.

- Asset Serialization: Assign unique IDs to each rental item, facilitating easy tracking and management.

- Loss Prevention: Reduce the risk of lost or misplaced assets through accurate tracking.

5. Maintenance and Repair Routines

Effective maintenance and repair routines require precise tracking of equipment and parts. RFID Cable Tie Tags provide the necessary data to streamline these processes.

- Scheduled Maintenance: Track maintenance schedules and ensure timely servicing of equipment.

- Repair Tracking: Monitor the repair history of each asset, enhancing accountability and efficiency.

How to Implement RFID Cable Tie Tags

Implementing RFID Cable Tie Tags into your existing systems is straightforward. Here’s a step-by-step guide to help you get started:

Step 1: Assess Your Needs

Determine the specific requirements of your organization. Identify which assets need tracking and what information needs to be stored on the tags.

- Identify Critical Assets: Focus on high-value or frequently used assets.

- Define Data Requirements: Decide what information will be encoded on the tags, such as serial numbers, maintenance schedules, or location data.

Step 2: Choose the Right Tag

Select the appropriate RFID Cable Tie Tag based on your memory and frequency needs.

- Memory Capacity: Choose between NTAG213, NTAG215, or NTAG216 based on your data storage requirements.

- Frequency: Decide between LF and HF tags depending on the read range and application.

Step 3: Customize and Order

Customize the tags to fit your branding and data needs.

- Printing and Encoding: Add logos, QR codes, or pre-encode data during the manufacturing process.

- Bulk Orders: Take advantage of bulk pricing for larger quantities.

Step 4: Integrate with Your Systems

Ensure that your existing RFID readers and software are compatible with the new tags.

- System Compatibility: Verify that your readers support the frequency and protocol of the tags.

- Software Integration: Update your asset management software to incorporate data from the RFID tags.

Step 5: Deploy and Train

Implement the tags across your organization and train staff on their usage.

- Deployment Strategy: Roll out the tags in phases to manage the transition smoothly.

- Staff Training: Educate employees on how to use RFID readers and manage the tagged assets.

Customization and Branding Options

Customization is a key advantage of RFID Cable Tie Tags, allowing businesses to tailor the tags to their specific needs and branding requirements.

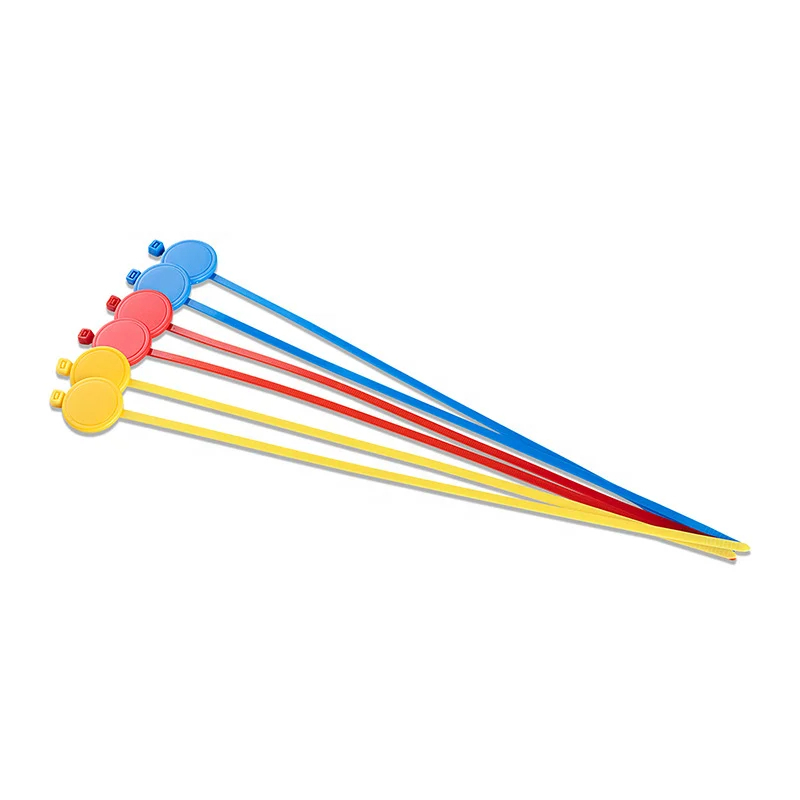

Custom Shapes and Sizes

Our tags are available in various shapes and sizes to fit different applications.

- Standard Sizes: Common sizes like 200×4.6mm cater to standard bundling needs.

- Custom Dimensions: Request custom sizes to fit unique or specialized applications.

Printing and Encoding Services

Enhance the functionality and appearance of your tags with custom printing and encoding.

- Branding: Print your company logo or specific identifiers directly onto the tags.

- Pre-Encoded Data: Load essential data onto the tags before deployment, saving time and ensuring consistency.

Bulk and Wholesale Options

For large-scale implementations, we offer bulk and wholesale options to meet your demands.

- Cost-Effective Pricing: Benefit from lower prices when ordering in bulk.

- Scalable Solutions: Easily scale your RFID tracking system as your business grows.

Durable Materials

Choose from a range of durable materials to ensure longevity and resilience.

- Nylon: Offers flexibility and strength, ideal for various environments.

- ABS and Other Materials: Select materials that best suit your operational conditions and application needs.

Environmental Impact and Sustainability

Sustainability is increasingly important in today’s business practices. RFID Cable Tie Tags contribute to environmentally friendly operations in several ways.

Reusable and Recyclable

Our RFID Cable Tie Tags are designed for reusability, reducing waste and promoting a circular economy.

- Reusability: Releasable ties can be removed and reused multiple times, minimizing the need for replacements.

- Recyclable Materials: Made from recyclable materials like nylon, contributing to waste reduction.

Energy Efficiency

Passive RFID tags, like those used in our cable ties, require no power source, making them an energy-efficient option.

- No Batteries Needed: Operate without the need for internal power sources, reducing energy consumption.

- Long Lifespan: Durable construction ensures that tags remain functional for extended periods, lowering the environmental impact.

Reduced Waste

By eliminating the need to cut and discard cable ties for adjustments, RFID Cable Tie Tags help reduce material waste.

- Sustainable Practices: Promote responsible usage and disposal of materials.

- Cost Savings: Reusing tags not only benefits the environment but also saves costs on purchasing new ties.

Customer Reviews and Testimonials

Real-world feedback highlights the effectiveness and reliability of RFID Cable Tie Tags. Here’s what our customers have to say:

John D., Warehouse Manager:

“Implementing RFID Cable Tie Tags has revolutionized our inventory management process. The ability to track assets in real-time has significantly improved our operational efficiency.”

Sarah L., Electrical Inspector:

“The durability of these tags in harsh environments is impressive. They remain readable even after multiple cleaning cycles, ensuring consistent performance.”

Mark T., Rental Service Owner:

“Using RFID Cable Tie Tags for our rental inventory has streamlined our tracking and reduced loss rates. The clear identification through unique numbering is a game-changer.”

Frequently Asked Questions (FAQs)

1. What is an RFID Cable Tie Tag?

An RFID Cable Tie Tag is a cable tie equipped with an RFID transponder, allowing for wireless data communication and enabling functions such as tracking, serialization, and product identification.

2. How do RFID Cable Tie Tags improve inventory management?

They provide real-time tracking and accurate identification of assets, reducing manual errors and enhancing the efficiency of inventory control systems.

3. Are RFID Cable Tie Tags durable?

Yes, they are made from robust materials like nylon and are resistant to harsh environments and cleaning processes, ensuring long-term functionality.

4. Can RFID Cable Tie Tags be reused?

Absolutely! Releasable ties allow the tags to be easily removed and reused, promoting sustainability and reducing waste.

5. What frequencies do these tags operate at?

They operate at LF – 125 kHz for read-only tags and HF – 13.56 MHz for rewritable tags.

6. How are the tags customized?

Customization options include different shapes and sizes, printing of logos or QR codes, and pre-encoding of data to suit specific application needs.

7. What is the maximum read range for these tags?

The operating distance can be up to 100 mm, depending on the reader’s power and the environment.

8. Do you offer bulk orders and discounts?

Yes, we provide bulk and wholesale options with competitive pricing to accommodate large-scale implementations.

9. How do I apply the RFID Cable Tie Tags?

Simply peel off the adhesive backing and securely fasten the tag to your cable bundle. Ensure the surface is clean for optimal adhesion.

10. What support do you offer after purchase?

We offer comprehensive customer support, including technical assistance, customization guidance, and warranty services to ensure your satisfaction.

Why Choose Our RFID Cable Tie Tags?

Selecting the right RFID Cable Tie Tag supplier is crucial for maximizing the benefits of RFID technology. Here’s why our tags stand out in the market:

Superior Quality and Durability

Our RFID Cable Tie Tags are crafted from high-grade materials, ensuring they withstand the rigors of industrial environments. The robust construction guarantees longevity, making them a reliable choice for long-term asset management.

- High-Quality Materials: Utilizes durable nylon and ABS for resilience.

- Rigorous Testing: Each tag undergoes stringent quality checks to ensure performance and reliability.

Advanced Security Features

Security is paramount in RFID applications. Our tags incorporate advanced security measures to protect your data and prevent unauthorized access.

- Encryption: Equipped with secure encryption protocols to safeguard information.

- Authentication: Features authentication via ECC and unique identifiers to ensure data integrity.

Customization Flexibility

We understand that different industries have unique needs. Our customization options allow you to tailor the RFID Cable Tie Tags to your specific requirements.

- Print Options: Add logos, serial numbers, or QR codes for enhanced branding and functionality.

- Variety of Sizes: Choose from a range of sizes to fit various applications, including 200×4.6mm tags.

Competitive Pricing and Bulk Orders

We offer competitive pricing without compromising on quality. Whether you need a small batch or a large order, we provide cost-effective solutions to meet your demands.

- Affordable Rates: High-quality tags at a fraction of the cost of competitors.

- Bulk Discounts: Special pricing for large orders, making it economical for extensive deployments.

Exceptional Customer Support

Our dedicated support team is always ready to assist you with any queries or issues, ensuring a smooth experience from purchase to implementation.

- Technical Assistance: Expert guidance on integrating and using RFID tags.

- Responsive Service: Quick response times to address your needs promptly.

Fast and Reliable Shipping

We prioritize timely delivery to ensure you can implement RFID tracking without delays.

- Efficient Logistics: Reliable shipping partners ensure your orders arrive on time.

- Secure Packaging: Tags are shipped in protective packaging to prevent damage during transit.

Conclusion: Key Takeaways

RFID Cable Tie Tags are a game-changer in product identification and management, offering a blend of traditional cable tie functionality with advanced RFID technology. Here are the most important points to remember:

- Innovative Solution: Combines the durability of cable ties with RFID for enhanced tracking and identification.

- Enhanced Efficiency: Streamlines processes in inventory management, asset tracking, and maintenance routines.

- Durable and Reliable: Built to withstand harsh environments and resistant to cleaning processes.

- Customizable: Offers various sizes, shapes, and printing options to suit different needs.

- Cost-Effective: Reusable and recyclable, reducing waste and saving costs over time.

- Advanced Security: Features like AES encryption and unique ID numbers ensure data protection.

- Wide Applications: Ideal for resource management, electrical inspection, logistics, rental services, and more.

- Easy Implementation: Simple to apply and integrate with existing RFID systems.

- Positive Customer Feedback: Proven effectiveness across various industries.