How RFID Wash Care Labels are Transforming the Clothing Industry?

Radio Frequency Identification (RFID) technology has revolutionized numerous industries, from logistics and healthcare to manufacturing and retail.

In large-scale tool management, it is essential to inventory, query, and verify tools that require maintenance, as well as to manage the borrowing and return of tools. Relying solely on personnel for these tasks can lead to an overwhelming workload, making it increasingly difficult to manage effectively. This is where RFID anti-metal tags become indispensable. Today, we will share the benefits of applying RFID anti-metal tags in tool management. Let’s explore this together.

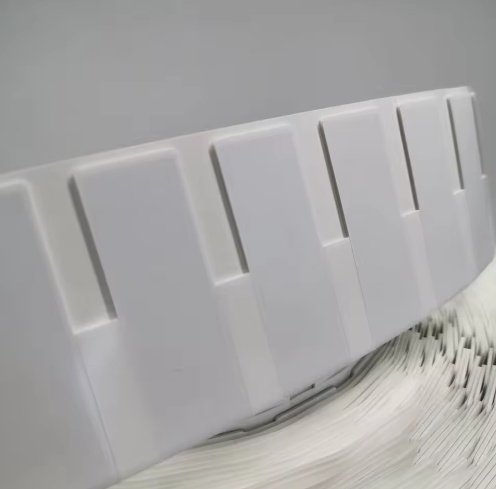

By utilizing RFID tags as unique identifiers for each tool, a one-to-one correspondence is established. When borrowing and returning tools, the system automatically recognizes the user’s identity, enabling a self-service borrowing process without the need for personnel intervention. The diversity of tool tag styles caters to the practical needs of different industries, with RFID anti-metal sticker being particularly prevalent in tool management. These tags come in embedded and adhesive styles. As the market matures, the cost-effectiveness of RFID anti-metal sticker continues to improve.

The introduction of automated management applications using RFID anti-metal tags maintains high efficiency and intelligent systems in tool management. By enhancing RFID reader technology and customizing tool cabinets equipped with intelligent antennas, the accuracy and efficiency of tool management can be further improved, facilitating resource sharing between organizations and units.

Prevention and Reduction of Tool Loss and Theft:

RFID tags help track tools accurately, reducing the chances of loss or theft.

Simplified Tool Borrowing and Returning Processes:

The automated system streamlines the borrowing and returning of tools, making it more efficient.

Real-time Data Updates:

The system provides real-time updates to avoid tool stagnation in storage and timely alerts for regular maintenance.

Reduced Personnel Investment:

A transparent management model aligns with the actual needs of social development, minimizing the need for extensive personnel involvement.

The intent behind the RFID tool management solution is to create a smart and portable system, which is realized through the integration of relevant technological devices. With the continuous advancement of big data in recent years, the application of radio frequency technology is expanding across various industries. We welcome those with technical management needs to contact us for more details!

In conclusion, this introduction to the benefits of RFID anti-metal tags in tool management , their importance in enhancing efficiency and security. Interested parties are encouraged to reach out for further information.

Our company has developed over the years and now operates four physical branches in Hong Kong, Foshan, Hubei, and Wuhan, specializing in RFID tags. Our product range includes zip tie RFID tags, nail RFID tags, RFID laundry tags, RFID vehicle tags, and anti-metal RFID tags, among other personalized custom options.

Newest trends and common knowledge in RFID laundry tags.

Radio Frequency Identification (RFID) technology has revolutionized numerous industries, from logistics and healthcare to manufacturing and retail.

RFID 1K F08 inlays, also known as RFID inlay stickers or transponders, are versatile and unfinished components that can be utilized in a wide range of applications.

In the bustling world of hospitality, where every detail counts, managing laundry efficiently can make or break guest satisfaction.

Didn’t find what you want? Ask our manager for help!