Ultimate Guide to RFID Keyfobs: Understanding Mifare S50 1K Technology in 2024

RFID keyfobs are small, contactless devices using radio-frequency tech for secure access. The Mifare S50 1K operates at 13.56 MHz for reliable, efficient control.

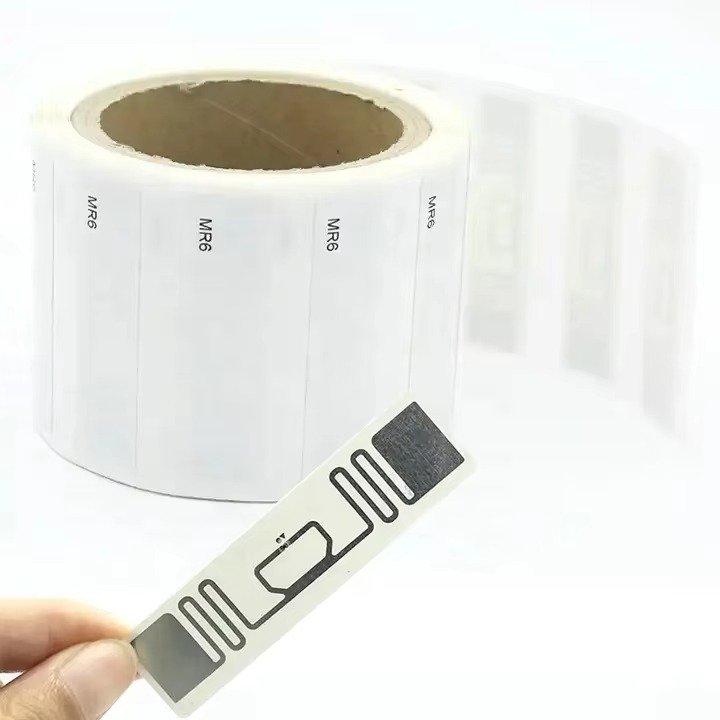

RFID tag manufacturing is a precision-driven industrial process that combines materials engineering, electronics assembly, and strict quality control. Each step directly affects tag performance, read reliability, and long-term durability in real-world applications such as logistics, retail, asset tracking, and industrial laundry.

Below is a clear, production-oriented overview of how standard RFID labels and tags are manufactured.

The manufacturing process begins with the RFID inlay, which is the functional core of the tag. Each inlay consists of a microchip bonded to a carefully tuned antenna.

Pre-produced RFID inlays are supplied in rolls and fed into a lamination line together with:

A printable face material (paper, PET, or synthetic film)

A pressure-sensitive adhesive layer (commonly industrial-grade 3M adhesive)

Using controlled heat and pressure, the lamination machine bonds these layers into a stable, multi-layer structure. The result is a semi-finished RFID label where the inlay is securely embedded between the face stock and adhesive backing. This step ensures mechanical stability and protects the chip and antenna during downstream processing.

Once laminated, the material advances to die-cutting. At this stage, precision tooling defines the final shape and size of the RFID tag.

A die-cutting machine cuts through the face material and adhesive while preserving the liner underneath. This creates individual tag shapes—rectangular, square, round, or custom—while keeping them arranged on a continuous roll.

Accuracy at this stage is critical. Improper die-cut depth or misalignment can damage the antenna or affect read performance, especially for UHF RFID tags.

After die-cutting, the RFID tags are still part of a wide master roll. To make them usable for labeling machines or manual application, the roll is processed through a slitting machine.

Slitting divides the master roll into multiple narrow rolls, each with consistent width, tension, and roll diameter. These finished rolls are now suitable for printing, encoding, and on-site application by the end user.

Quality assurance is a non-negotiable step in RFID tag manufacturing. Every finished roll undergoes RFID performance testing, which typically includes:

Chip functionality verification

EPC or UID readability checks

Frequency and sensitivity validation

Visual inspection for lamination and die-cut accuracy

Non-functional tags are automatically identified and removed. Only tags that meet electrical and mechanical standards proceed to final packaging. This ensures consistent performance when tags are deployed in customer systems.

The RFID tag production flow can be summarized as:

Inlay lamination – bonding chip, antenna, face stock, and adhesive

Die-cutting – defining tag shape and size

Slitting – converting master rolls into application-ready rolls

Testing and packaging – verifying performance and preparing for shipment

Each step is designed to protect inlay integrity while ensuring scalability and cost efficiency.

An RFID tag stores digital data and transmits it wirelessly to an RFID reader using radio frequency signals. When energized by the reader, the tag responds with its unique ID or stored information, enabling automatic identification without physical contact or line-of-sight.

An RFID label is a self-adhesive RFID tag that combines an inlay with printable label material. It functions like a standard label but adds wireless identification capabilities, making it ideal for logistics, retail, and inventory applications.

RFID stickers (labels) are widely used for:

Inventory and warehouse management

Asset and equipment tracking

Supply chain visibility

Access control and identification badges

Retail automation and loss prevention

Library and media management

Anti-counterfeiting and authentication

Airline baggage tracking

The exact application depends on tag frequency (LF, HF, UHF), chip type, and system design.

RFID performance is not defined by the chip alone. Lamination quality, antenna alignment, adhesive selection, and testing rigor all directly impact read range, consistency, and lifecycle reliability.

For businesses deploying RFID at scale, working with a manufacturer that controls the full production process ensures:

Stable read performance

Lower failure rates

Better compatibility with printers and readers

Predictable long-term costs

Newest trends and common knowledge in RFID laundry tags.

RFID keyfobs are small, contactless devices using radio-frequency tech for secure access. The Mifare S50 1K operates at 13.56 MHz for reliable, efficient control.

UHF RFID inlays offer long-range tracking and customization, enhancing efficiency and accuracy in logistics, inventory management, and asset tracking.

The 20mm PPS NFC Laundry Clothing Tag represents a significant advancement in the application of Near Field Communication (NFC) technology within the textile and laundry industries.

Didn’t find what you want? Ask our manager for help!