Understanding RFID Tags in Laundry Management: Key Facts for Industry Professionals

RFID Tags enables wireless identification and communication, making it a leading innovation with vast applications and market potential in the 21st century.

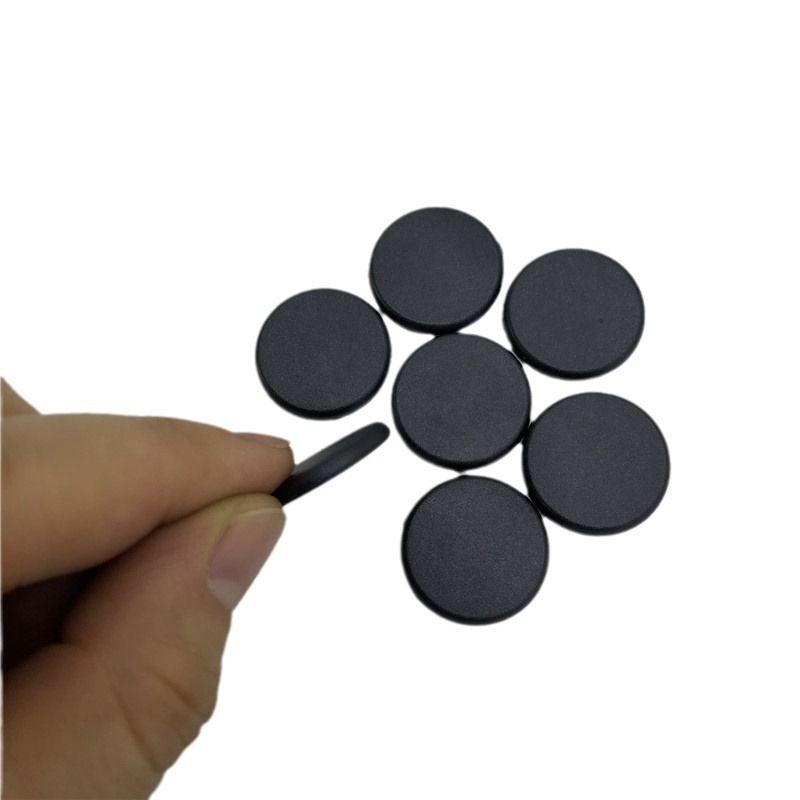

RFID (Radio Frequency Identification) laundry tags are RFID technology products used in the laundry industry. They are typically employed to track and monitor clothing throughout the laundering process, improving the efficiency and accuracy of laundry services.

These tags have several characteristics, including:

In China, the application of RFID technology in the laundry industry is becoming increasingly common, contributing to improved quality and efficiency of laundry services while promoting the intelligent development of the laundry industry.

RFID laundry tags can use various chips and materials, and the specific choice usually depends on application requirements and environmental conditions. Here are some commonly used chips and materials:

The most popular option is the 70x15mm non-woven RFID laundry tag, which utilizes the NXP U9 chip. This tag features a globally unique identification code and can withstand more than 200 industrial washing cycles. It can be detected by metal detectors and offers advantages such as thin thickness, long read distance, pressure resistance, and high-temperature tolerance.

High-Temperature Resistant Materials: Such as non-woven fabric, PPS, or silicone materials, suitable for high-temperature washing and disinfection environments.

In summary, the integration of RFID technology in China’s laundry industry is enhancing operational efficiency and service quality. The use of durable tags, such as the popular 70x15mm non-woven RFID laundry tag with the NXP U9 chip, enables precise tracking and monitoring of garments, supporting the industry’s move towards intelligent automation. This development not only streamlines processes but also helps improve overall customer satisfaction.

Newest trends and common knowledge in RFID laundry tags.

RFID Tags enables wireless identification and communication, making it a leading innovation with vast applications and market potential in the 21st century.

In the fast-paced world of hospitality, where every detail counts towards guest satisfaction, efficient laundry management stands as a pivotal element. From plush towels to crisp bed linens, hotels and resorts strive for excellence in cleanliness and presentation.

Traditional washing companies are using a single manual inventory method to try to identify lost or stolen textiles.

Didn’t find what you want? Ask our manager for help!