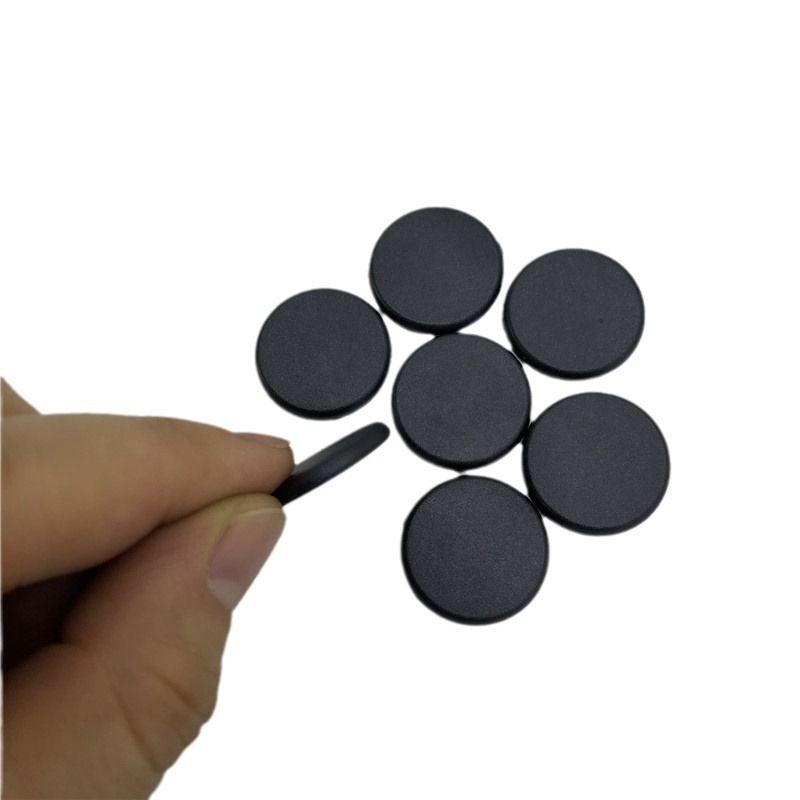

Laundry Industries with 20mm PPS NFC Laundry Clothing Tag

The 20mm PPS NFC Laundry Clothing Tag represents a significant advancement in the application of Near Field Communication (NFC) technology within the textile and laundry industries.

From aerospace to automotive, energy to healthcare, on-metal RFID tags are transforming how industries manage their metallic assets. They play a crucial role in optimizing inventory, boosting productivity, and preventing loss and theft.

The presence of metal can scatter and absorb RFID signals, hindering the performance of conventional RFID tags. On-metal tags are specifically engineered to overcome these obstacles and ensure dependable communication.

Yes, specialized RFID tags, known as on-metal RFID tags, are designed to function effectively on metal surfaces. They utilize unique designs and technologies to overcome the challenges posed by metal interference. Standard RFID tags may experience reduced read range or fail to operate correctly when placed directly on metal. Therefore, on metal RFID tag will be adopted in metal related items.

Metal can interfere with RFID signals, but it doesn’t completely stop them. Metal reflects and absorbs the radio waves used by RFID systems. This interference can significantly reduce the read range and reliability of standard RFID tags. However, on-metal RFID tags are engineered with features like specialized antennas and shielding to mitigate these effects, allowing them to function properly on or near metallic objects.

On-metal RFID tags are designed to achieve a greater read range than standard RFID tags when affixed to metal surfaces. This is accomplished through design enhancements that amplify signal strength and penetration.

As these RFID tags are often employed in industrial or challenging settings, they are constructed to be exceptionally durable and resilient against environmental factors like moisture, temperature fluctuations, and physical impacts.

An anti-metal RFID tag, also known as an on-metal RFID tag, is a type of RFID tag specifically designed to be attached to metal surfaces without the metal interfering with the tag’s performance. These tags are engineered to overcome the challenges posed by metal, which can reflect, absorb, or detune RFID signals, by using specialized antenna designs and often incorporating a shielding layer or ferrite material to isolate the tag from the metal surface.

The terms “RFID tag” and “RF tag” are often used interchangeably, but there can be a slight difference in their connotation.

RFID Tag: This term specifically refers to tags that use Radio Frequency Identification (RFID) technology. RFID tags are a subset of RF tags. They always operate using radio waves to communicate with a reader and are used for identification and tracking purposes.

RF Tag: This term is a bit broader. “RF” stands for Radio Frequency. An RF tag, therefore, is any tag that uses radio waves for communication. While all RFID tags are RF tags, not all RF tags are necessarily RFID tags.

In most practical contexts, especially in discussions about tracking and identification, the two terms are used synonymously. However, technically, RFID is a specific type of RF technology.

On-metal RFID tags are purpose-built to adhere seamlessly to metal surfaces and perform flawlessly in environments with abundant metal equipment or infrastructure. Their advanced design effectively addresses the challenges of metal interference, unlocking new levels of precision in tracking and managing metal assets.

Real-Time, Detailed Asset Visibility: Gain an unprecedented understanding of your assets’ location and status in real time.

Enhanced Inventory Precision: Attain near-perfect inventory control by eliminating guesswork, whether it’s raw materials, components, or finished goods.

Comprehensive Audit Trails: Generate thorough records of asset movements, creating an audit trail that streamlines compliance with industry regulations and quality control benchmarks.

Streamlined Maintenance Planning: Eliminate manual maintenance scheduling and unforeseen equipment downtime. On-metal RFID tags enable proactive asset maintenance, minimizing costly disruptions and maximizing operational lifespan.

Global Frequency Compatibility: Many on-metal RFID tags are designed to operate on a range of frequencies, making them suitable for use in various regions around the world and ensuring compliance with local regulations.

Advanced Chip Technology: Newer on-metal tags often incorporate advanced RFID chips that offer improved read sensitivity, faster data processing, and enhanced security features like encryption and authentication.

Versatile Mounting Options: On-metal RFID tags come with various mounting choices, including high-strength adhesives, rivets, screws, and even welding, to accommodate different application requirements and surface types.

High performance on and off metal

Ability to withstand extreme temperatures and harsh environments

Variety of form factors

Available in self-adhesive labels and hard tags

Multiple attachment options

Compliant with industry regulations and quality control standards.

What are on-metal RFID tags, and how do they operate?

On-metal tags are specialized RFID tags engineered to adhere to and function effectively on metal surfaces. They employ unique antenna designs and shielding methods to overcome metal-induced interference, ensuring accurate asset identification and tracking.

In which industries are on-metal RFID tags typically utilized?

On-metal RFID tags find applications across diverse sectors, including manufacturing, logistics, construction, energy, healthcare, oil and gas, defense, and others where precise asset tracking and management of metal assets are critical.

What makes on-metal RFID tags more accurate than conventional RFID tags?

On-metal RFID tags are meticulously engineered to mitigate the effects of metal interference, guaranteeing accurate and reliable asset tracking, even on metal surfaces. Their specialized design enables the precise transmission and reception of RFID signals in challenging conditions.

Can on-metal RFID tags be integrated with pre-existing RFID systems?

Yes, on-metal RFID tags are designed for seamless integration with existing RFID systems. They are compatible with a broad range of RFID readers and software solutions, ensuring a smooth implementation.

How do on-metal RFID tags help minimize asset downtime?

On-metal RFID tags enable proactive maintenance scheduling by monitoring asset usage and automatically generating maintenance alerts. This helps reduce unexpected downtime and maintain smooth operations.

What kind of data insights can on-metal RFID tags provide?

On-metal RFID tags generate valuable data insights, including asset location, usage patterns, and maintenance history. This data facilitates data-driven decision-making, optimizing processes and resource allocation.

Can on-metal RFID tags assist with regulatory compliance and audits?

Yes, on-metal RFID tags generate comprehensive audit trails and streamline compliance with industry regulations and quality control standards, making audits more efficient and precise.

How can on-metal RFID tags enhance inventory management?

On-metal RFID tags provide real-time visibility into inventory, helping organizations maintain accurate stock levels, minimize overstocking or understocking, and streamline inventory management processes for greater efficiency.

How do on-metal RFID tags support sustainability and environmental responsibility?

On-metal RFID tags help minimize waste and enhance resource utilization through efficient asset tracking and management. By optimizing inventory and reducing asset downtime, they contribute to more sustainable and environmentally conscious business practices.

Can on-metal RFID tags be tailored to meet specific business requirements?

Yes, on-metal RFID tags can be customized to align with your specific industry and use case. Customization options often include tag size and shape, data encoding, branding, and specialized coatings.

On-metal RFID tags are revolutionizing asset management across industries. Their ability to function reliably on metal surfaces, coupled with features like extended read range, durability, global frequency compatibility, advanced chip technology, and versatile mounting options, makes them an indispensable tool for organizations seeking to optimize operations, improve inventory control, and enhance overall efficiency. By implementing on-metal RFID technology, businesses can unlock valuable data insights, streamline processes, and achieve a significant return on investment.

Newest trends and common knowledge in RFID laundry tags.

The 20mm PPS NFC Laundry Clothing Tag represents a significant advancement in the application of Near Field Communication (NFC) technology within the textile and laundry industries.

Transform dining with NFC Menu Tags! Effortlessly access digital menus by scanning or tapping, ensuring quick, seamless ordering for an enhanced customer experience.

In the fast-paced world of hospitality, where every detail counts towards guest satisfaction, efficient laundry management stands as a pivotal element. From plush towels to crisp bed linens, hotels and resorts strive for excellence in cleanliness and presentation.

Didn’t find what you want? Ask our manager for help!