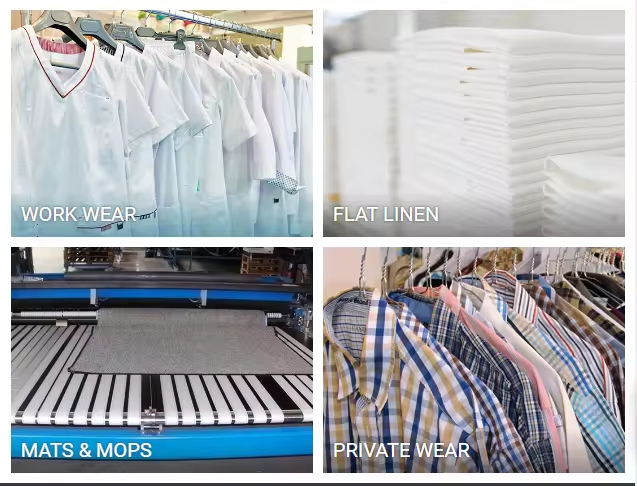

Durable Fabric Textile UHF RFID Laundry Tags: Essential for Efficient Management

Fabric Textile UHF RFID Laundry Tags are specially designed RFID transponders tailored for textile products subjected to various industrial cleaning processes, such as sterilization, washing, and ironing.