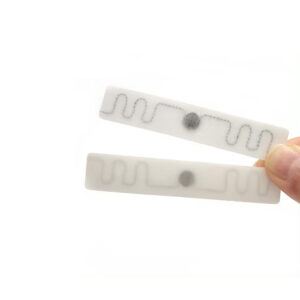

UHF Washable RFID Fabric Laundry Tags

UHF Washable RFID Fabric Laundry Tags, produced with high-tech UHF technology (860-960 MHz), adhere to international standards like EPC Class1 Gen2 and ISO 18000. These UHF Textile linen laundry tags provide flexibility and robustness capable of withstanding more than 200 wash cycles and pressure up to 60 bar. The standout feature of the UHF RFID fabric laundry tag is its ability to facilitate mass reading from a few meters distance, presenting a highly efficient tool for laundry management.

Description

| Item Name: | UHF Washable RFID Fabric Laundry Tags |

| RFID Standard: | ISO/IEC 18000-6 TypeC (EPC Gen2) |

| Size&Weight: | 70×15 mm, 0.6g |

| Chip Type: | Impinj Monza 4QT,NXP U CODE 8,NXP U CODE 9 |

| EPC Memory: | 128bits |

| User Memory: | 512bits |

| Read Range(2W ERP FCC): | 8m |

| Read Range(2W ERP ETSI): | 8m |

| Tagging: | Sewing, Hot stamping adhesive |

| Estimated Lifetime: | 200 washing cycles or 3 years, whichever comes first |

| Washing Method: | Laundry, Dry cleaning |

| Water Extraction pressure: | 60 bar |

| Water Resistance: | Water resistant |

| Chemical Resistance: | Detergent, Softener, Bleach (Oxygen/ Chlorine), Alkali |

| Pre-drying in Tumbler: | 125 ºC for 15-20minute |

| Sterilization Temperature: | 135°C for 15-20minutes |

| Washing Temperature: | 90°C ,Up to 15min. |

| Humidity/ Temperature-Operating: | -20 to 110°C, 8 to 95%RH |

| Humidity/ Temperature-Storage: | -40 to 110°C, 8 to 95%RH |

1) UHF technology to read hundreds of tags simultaneously.

2) More than 8 foot reading distance.

3) New mechanical design for improved performance for flat linens.

4) Suitable for high-pressure extractors up to 60 bar.

5) Suitable for Autoclave sterilization.

6) Small, soft, flexible material ideal for textiles, linens, garments and accessories.

Installation

Stitch Tagging: To be stitched into the hem of a textile. Stitch the laundry tag away from the folding lines.

Heat Sealing: To be heat-sealed directly on the textile at +200°C (392°F), for 12~14s.

In Pouch: To be stitched like a standard care label. Stitch the laundry tag away from the folding lines.

How STRONG they are ?

①.Are the RFID chips be damaged under high temperatures? –✔ Our RFID textile laundry tag are designed to be used at 200 °C.

②How many times can we wash the tags that are attached to uniforms textile products? –✔Our RFID textile laundry tag can be washed more than 200 times guaranteed for 2 years after shipping.

③Are we going to spend prestigious uniforms textile products, continue to work in case of chip crush? –✔We designed our textile laundry tag to withstand 60 bars of pressure in the process of pressing your textile products.

④Where do you place RFID textile laundry tags on uniforms textiles? – ✔RFID textile laundry tag are installed according to the availability of the uniforms.