UHF RFID Textile Laundry Tag

RFID laundry tags are specifically designed for use in hotels, hospitals, dry cleaners, and airline blanket management. These tags are available in three main materials: PPS, silicone, and fabric.

Description

UHF RFID Textile Laundry Tag

RFID Fabric Laundry Tags .

RFID fabric laundry tags are commonly used in industrial laundry operations, hotel linens, and medical uniforms. These tags are highly resilient and can withstand high temperatures, making them capable of surviving over 200 wash cycles.

1) UHF technology to read hundreds of tags simultaneously.

2) More than 8 foot reading distance.

3) New mechanical design for improved performance for flat linens.

4) Suitable for high-pressure extractors up to 60 bar.

5) Suitable for Autoclave sterilization.

6) Small, soft, flexible material ideal for textiles, linens, garments and accessories.

Storage condition:-20-80℃,5-95%RH

Installation

Stitch Tagging: To be stitched into the hem of a textile. Stitch the laundry tag away from the folding lines.

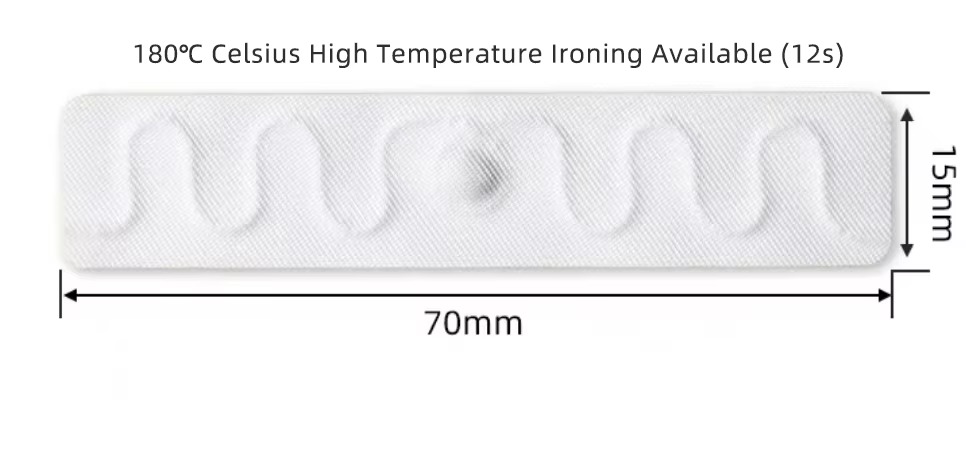

Heat Sealing: To be heat-sealed directly on the textile at +200°C (392°F), for 12~14s.

In Pouch: To be stitched like a standard care label. Stitch the laundry tag away from the folding lines.

-

Healthcare: Hospitals and other medical facilities use RFID linen tags to manage huge inventories of bed sheets, towels, scrubs, uniforms, and surgical linens. This helps reduce loss, manage laundry cycles, and ensure clean, fresh linens are always available as required.

-

Hotels: Managing linens is a huge task in the hotel industry, where thousands of items, from bedding to towels to curtains and robes, are in circulation. RFID linen tags simplify tracking, ensuring timely cleaning and replacement, and helps in detecting and preventing theft.

-

Restaurants: In the food service industry, RFID tags can monitor the usage and cleaning of uniforms, tablecloths, napkins, and chef’s aprons. This can improve cleanliness standards and aid in maintaining a polished, professional appearance.

-

Fashion Apparel Industries: RFID tags play a huge role in tracking items throughout the supply chain, from production to retail. They can provide valuable information like origin, travel history, and even details about the fabric and care instructions.

-

Workwear/Fire Retardant Clothing: Companies can use RFID tags to track and manage specialty clothing items. This can include ensuring fire retardant or other protective clothing is inspected regularly, properly cleaned, and replaced as necessary.

-

Footwear and Masks: Especially important in industries like healthcare and construction where safety is critical, tracking the usage, cleaning, and maintenance of items like masks and safety shoes can be simplified with the use of RFID tags.

-

Mats and Mops: For businesses providing cleaning services or managing large facilities, RFID tags on mats and mops can help track usage and maintenance, ensuring clean and effective tools at all times.