Understanding RFID Labels and Tags: Everything You Need to Know

RFID labels use radio waves for fast, accurate tracking without line of sight. Ideal for asset management, inventory, and real-time data across industries.

In the rapidly evolving landscape of logistics and supply chain management, the UHF RFID label emerges as a game changer. These RFID tags offer enhanced inventory tracking, improved operational efficiency, and significant cost savings. By utilizing UHF RFID technology, businesses can automate and streamline their warehouse processes, leading to better accuracy and real-time visibility across their supply chains. The benefits of adopting UHF RFID labels go beyond mere identification; they transform how products are managed from storage to shipment.

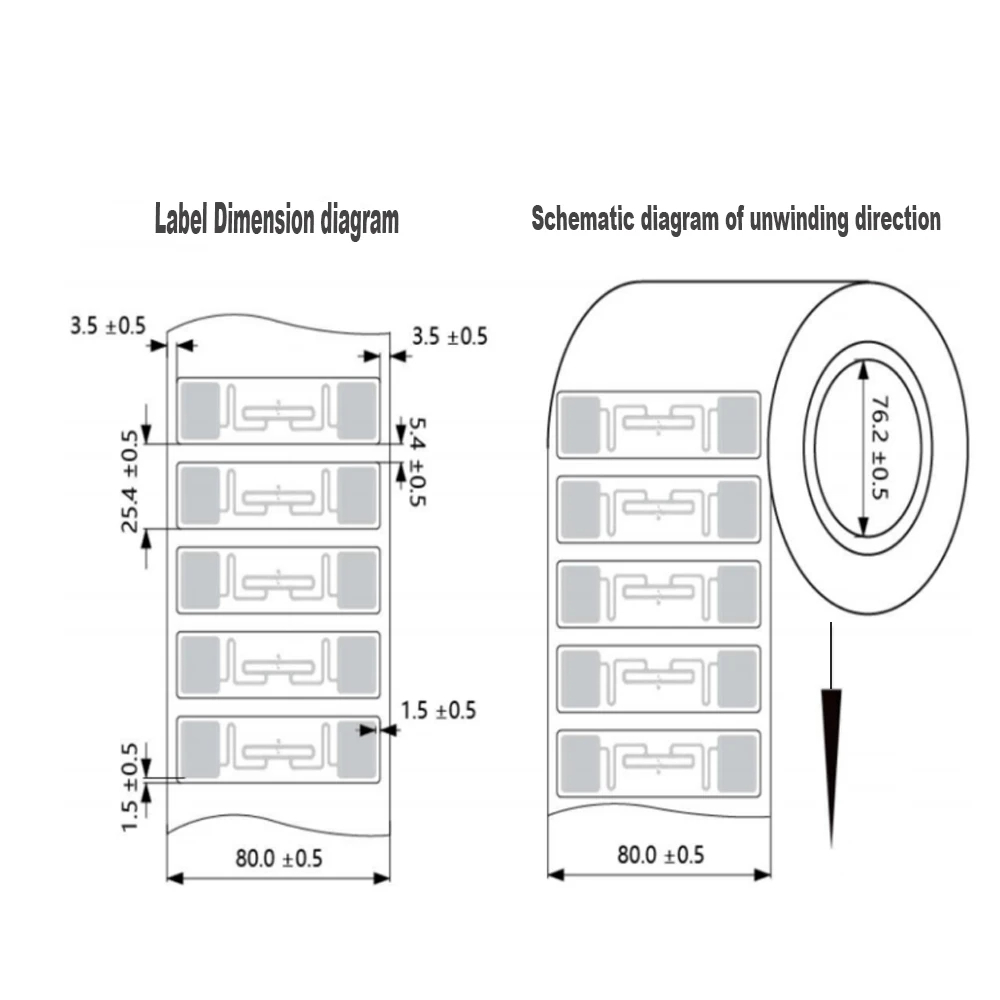

A UHF RFID label is a passive RFID tag that operates in the ultra-high frequency (UHF) range, typically around 915 MHz. These labels are designed to store and transmit data without the need for direct line-of-sight scanning, unlike traditional barcodes. The labels consist of an inlay that includes a chip and an antenna, all encapsulated in an adhesive material, enabling easy attachment to various products and packaging.

The passive nature of UHF RFID labels means they do not require a battery; they derive energy from the reader’s radio frequency signal. This allows them to be lightweight, low-cost, and environmentally friendly.

Adopting UHF RFID tags offers numerous advantages for businesses in the logistics sector.

Enhanced Data Capture: UHF RFID labels can be read at greater distances and can be scanned in bulk, enabling the real-time tracking of multiple items simultaneously. This capability drastically reduces the time spent scanning products individually.

Increased Accuracy: By minimizing manual entry errors and providing instant feedback on inventory counts, UHF RFID labels enhance overall inventory accuracy. This reliability leads to better supply chain management and informed decision-making.

Cost-Effective Operations: The initial investment in RFID technology can be offset by substantial savings in labor costs and reduced inventory shrinkage. Many companies have reported lower stockholding costs and improved cash flow after implementing UHF RFID systems.

n today’s fast-paced logistics environment, efficient inventory management is crucial. UHF RFID labels play a pivotal role in achieving this goal.

Real-Time Visibility: By utilizing UHF RFID in their operations, companies can gain live data on their inventory status. This visibility helps in optimizing stock levels and ensuring that products are always available when needed.

Streamlined Processes: With automated scans of RFID labels upon entry and exit from the warehouse, inventory counts can be automatically updated, significantly speeding up both the receiving and shipping processes.

Reduction in Loss and Misplacement: The unique identification capabilities of UHF RFID tags minimize the chances of inventory loss or misplacement. Companies can locate their assets quickly, leading to improved operational efficiency.

Antenna Size | 50×30mm/70x15mm/94×22mm |

Wet Inlay/Label Size | 54×34mm/73x20mm/94×22mm(customized) |

Label Material | Coated Paper/PET/Fragile Paper |

Working Temp | -40~+85℃ |

Storage Temp | -40~+85℃ |

RFID Standard | ISO/IEC 18000-6C (EPC Gen2) |

Chip Type | NXP U code 8/9 |

EPC Memory | 128/96 bits |

TID Memory | 96/96 bits |

Read Range(2W ERP) | 25m |

Data Storage | > 10 years |

Re-write | 100,000 times |

Customization | Printing LOGO, Barcode, Serial number, Encoding, Designing,etc |

Application | Apparel management Logistics management Document management Assets management, etc |

UHF RFID labels are versatile and can be applied across various logistics scenarios:

Warehouse Management: Automating stock takes and tracking inventory locations ensures that warehouses operate at maximum efficiency while reducing human errors.

Supply Chain Tracking: From production to delivery, UHF RFID labels allow for complete transparency in the supply chain, ensuring product integrity and real-time updates for all stakeholders involved.

Asset Tracking: Businesses can maintain a detailed account of all assets using UHF RFID, avoiding loss and improving.

The integration of UHF RFID technology in various industries, particularly in logistics and warehousing, presents not only operational efficiencies but also distinct environmental benefits.

Reduction in Waste: UHF RFID labels, particularly passive ones, do not require batteries. This significantly reduces electronic waste. Furthermore, by improving inventory accuracy and reducing overstock situations, companies can lower the volume of unsold products that contribute to landfill waste.

Energy Efficiency: Automated systems powered by UHF RFID technology operate more efficiently than manual processes. This efficiency translates into lower energy consumption over the lifecycle of operations. With real-time inventory management, businesses can better align production with demand, further minimizing unnecessary resource utilization.

Sustainable Operations: As more companies adopt sustainable practices, integrating UHF RFID can facilitate greener operations. By improving supply chain visibility and inventory optimization, businesses can reduce their carbon footprints, ultimately supporting global sustainability goals.

Passive RFID labels do not have an internal power source; they rely on energy harvested from the reader’s radio waves. Active RFID labels, on the other hand, contain batteries that allow for a greater range and additional functionalities. UHF RFID labels typically fall under the passive category.

UHF RFID labels, especially on-metal RFID variations, are designed to be used on various surfaces, including challenging materials like metal and water. However, it’s essential to choose the right type of label according to the surface for optimal performance.

The read range for UHF RFID labels can vary based on the tag design, reader sensitivity, and environmental factors, typically ranging from a few centimeters up to several meters. In optimal conditions, some tags can be read from up to 12 meters away.

It’s crucial to assess the environmental conditions in which the UHF RFID labels will be used. Look for labels with specific durability ratings, such as temperature resistance, moisture protection, and abrasion resistance. Manufacturers often provide specifications outlining the environmental adaptability of their RFID products.

While many UHF RFID labels are designed to work with standard UHF RFID readers, compatibility can depend on factors such as frequency bands and communication protocols. It is important to verify compatibility with both the label and the reader specifications before purchase.

UHF RFID labels can store a variety of data, including serial numbers, product information, inventory levels, and location data. The amount of data depends on the memory capacity of the RFID chip embedded in the label.

In conclusion, UHF RFID labels offer a comprehensive solution for organizations looking to improve their logistics and inventory management processes. Their efficient design, coupled with a wide range of applications and beneficial environmental impact, makes them a strong investment for businesses aiming for modernization and sustainability. By integrating UHF RFID technology, companies can enhance both operational efficiency and sustainability, driving positive outcomes in their logistics operations.

Newest trends and common knowledge in RFID laundry tags.

RFID labels use radio waves for fast, accurate tracking without line of sight. Ideal for asset management, inventory, and real-time data across industries.

Radio Frequency Identification (RFID) technology has revolutionized numerous industries, from logistics and healthcare to manufacturing and retail.

RFID tag is a technology that uses radio waves for non-contact two-way data communication to identify targets and obtain relevant data.

Didn’t find what you want? Ask our manager for help!