Laundry RFID Tag Manufacturers: Revolutionizing Laundry Management

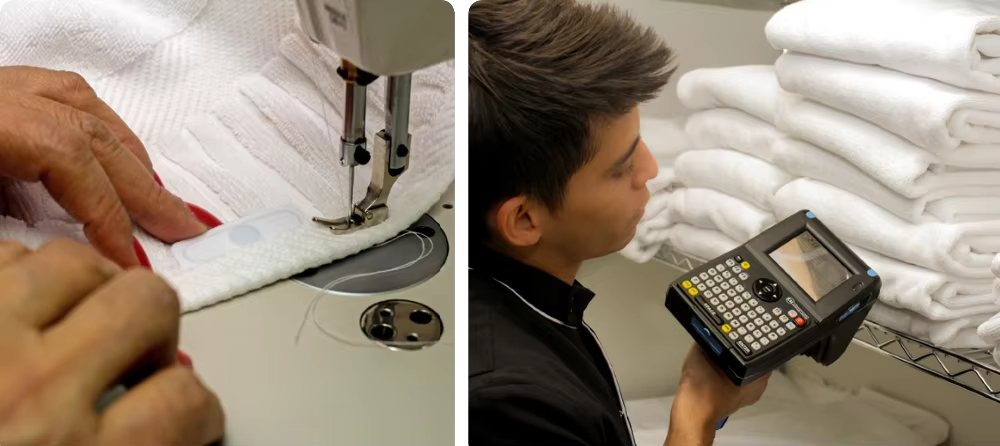

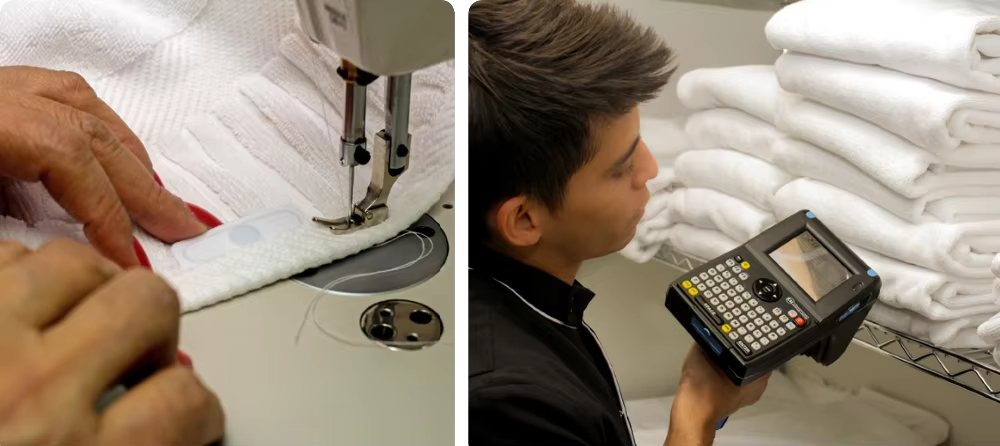

Explore how Laundry RFID Tag technology revolutionizes laundry services, enhancing tracking, efficiency, and service quality for commercial laundries, hospitals, and hotels.

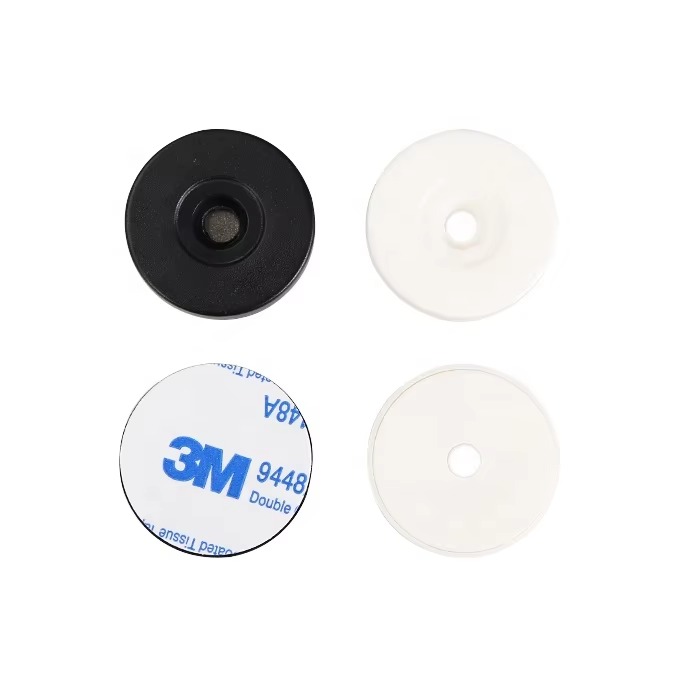

The TK4100 RFID Disc Tag is engineered for reliability and durability, making it an invaluable asset for organizations aiming to enhance their asset management processes, especially in challenging environments like industrial settings and logistics operations.

The TK4100 RFID Disc Tag is a versatile, durable, and reliable solution for asset management in demanding environments. Whether in industrial settings or logistics operations, its robust construction and efficient RFID technology make it an ideal choice for enhancing operational efficiency and asset security.

Newest trends and common knowledge in RFID laundry tags.

Explore how Laundry RFID Tag technology revolutionizes laundry services, enhancing tracking, efficiency, and service quality for commercial laundries, hospitals, and hotels.

Discover how UHF RFID labels streamline logistics and inventory management, enhancing efficiency, accuracy, and sustainability in your operations.

ISO15693 Washable PPS NFC Button Laundry Tag represents a significant advancement in RFID technology, can designed for applications for durability, reliability etc.

Didn’t find what you want? Ask our manager for help!