What is the production process of RFID tags

The creation of RFID tags involves a precise and efficient process, ensuring each RFID tag functions flawlessly. Here’s a breakdown of the key stages:

With the rapid advancement of information technology, enterprises are facing increasing challenges in material management and inventory control. Traditional counting methods are often time-consuming and prone to errors, failing to meet modern companies’ demands for efficient and accurate inventory management. To address this issue, RFID (Radio Frequency Identification) technology has emerged as a revolutionary solution. This article will explore the application of RFID technology in the inventory counting process and the numerous advantages it offers.

RFID tag technology is an automatic identification technology that transmits and exchanges information via radio waves. Its essential components include tags, readers, and data management systems. Tags are usually affixed to items and store detailed information about those items. The reader is responsible for reading the information sent by the tags and transmitting it to the data management system for further processing. The core of this technology lies in its ability to quickly and accurately identify specific items, allowing for the collection and management of large volumes of data.

In the inventory counting process, the application of RFID tag technology significantly enhances efficiency and accuracy. Traditional counting methods often rely on manual checks, which not only consume time but also are susceptible to human errors. With RFID technology, enterprises can simply bring the reader close to the goods, enabling quick recognition of all items in a short period, thus drastically increasing counting speed.

RFID technology can identify multiple RFID tags in a short time, often completing the counting of dozens or even hundreds of items within a second. In contrast, traditional barcode scanning typically requires individual scanning of each item, a process that is inefficient and error-prone.

When integrated with a data management system, the RFID system can achieve real-time data updates. As the reader retrieves information about the items, the relevant data is immediately fed back into the enterprise’s inventory management system. This real-time capacity allows companies to promptly monitor inventory status, preventing issues such as overstocking or shortages due to delayed information.

Traditional inventory counting methods often necessitate considerable manpower for data entry and verification. In contrast, RFID technology enables automated processing, reducing the need for human intervention, lowering labor costs, and improving both the efficiency and accuracy of the counting process.

In summary, the introduction of RFID tag has brought revolutionary changes to inventory counting, allowing enterprises to achieve efficient and precise objectives in inventory management. As RFID technology continues to develop and gain traction, more companies are expected to incorporate it into their material management practices, enhancing overall operational efficiency and market competitiveness. We have every reason to believe that RFID technology will play an increasingly crucial role in future inventory management, driving enterprises toward greater intelligence and efficiency.

Newest trends and common knowledge in RFID laundry tags.

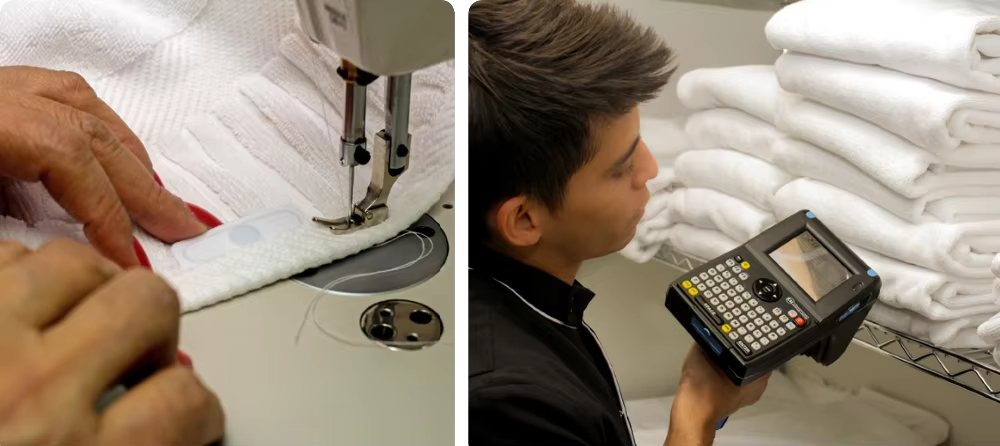

The creation of RFID tags involves a precise and efficient process, ensuring each RFID tag functions flawlessly. Here’s a breakdown of the key stages:

Fabric Textile UHF RFID Laundry Tags are specially designed RFID transponders tailored for textile products subjected to various industrial cleaning processes, such as sterilization, washing, and ironing.

Explore how Laundry RFID Tag technology revolutionizes laundry services, enhancing tracking, efficiency, and service quality for commercial laundries, hospitals, and hotels.

Didn’t find what you want? Ask our manager for help!