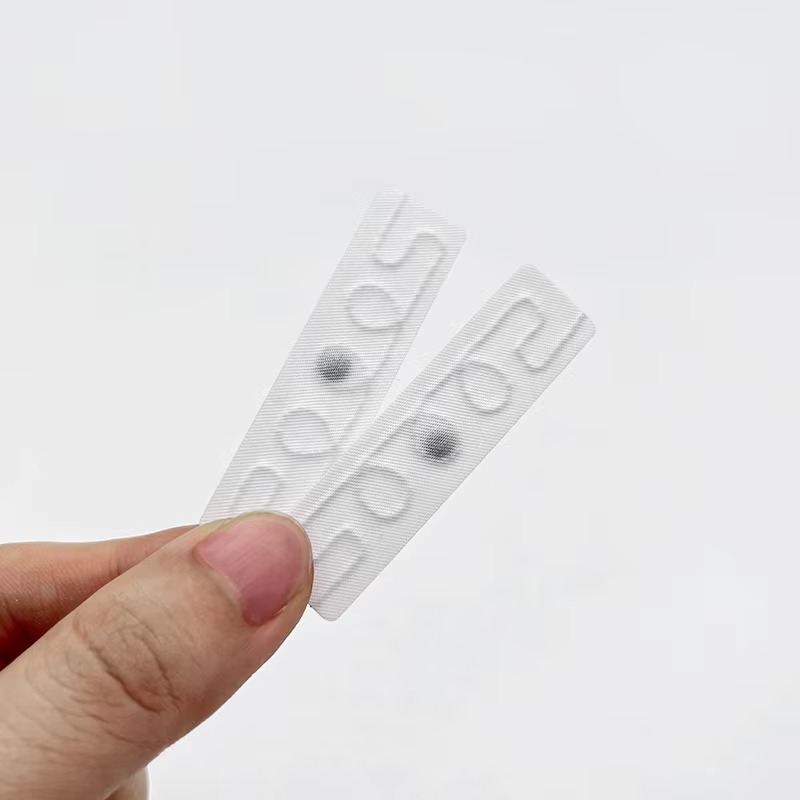

Textile Fabric RFID Laundry Tags

Textile Fabric RFID Laundry Tags, crafted with advanced UHF technology (860-960 MHz), comply with global standards such as EPC Class1 Gen2 and ISO 18000. These UHF Textile linen laundry tags offer a blend of flexibility and sturdiness that can endure over 200 wash cycles and pressure of up to 60 bar. The remarkable characteristic of the UHF RFID fabric laundry tag is its potential to permit mass reading from a few meters away, serving as a highly efficient instrument for laundry management.

Description

| Item Name: | Textile Fabric RFID Laundry Tags |

| RFID Standard: | ISO/IEC 18000-6 TypeC (EPC Gen2) |

| Size&Weight: | 70×15 mm, 0.6g |

| Chip Type: | Impinj Monza 4QT,NXP U CODE 8,NXP U CODE 9 |

| EPC Memory: | 128bits |

| User Memory: | 512bits |

| Read Range(2W ERP FCC): | 8m |

| Read Range(2W ERP ETSI): | 8m |

| Tagging: | Sewing, Hot stamping adhesive |

| Estimated Lifetime: | 200 washing cycles or 3 years, whichever comes first |

| Washing Method: | Laundry, Dry cleaning |

| Water Extraction pressure: | 60 bar |

| Water Resistance: | Water resistant |

| Chemical Resistance: | Detergent, Softener, Bleach (Oxygen/ Chlorine), Alkali |

| Pre-drying in Tumbler: | 125 ºC for 15-20minute |

| Sterilization Temperature: | 135°C for 15-20minutes |

| Washing Temperature: | 90°C ,Up to 15min. |

| Humidity/ Temperature-Operating: | -20 to 110°C, 8 to 95%RH |

| Humidity/ Temperature-Storage: | -40 to 110°C, 8 to 95%RH |

Features of Textile Fabric RFID Laundry Tags

1. Durable and Washable

Our washable RFID tags are meticulously designed to endure harsh laundry conditions. They can withstand up to 200 wash cycles, withstanding high temperatures during washing and drying processes. The durable materials and technology used ensure that these tags can be sewn into various items, including linens and garments, without compromising their integrity. Whether it’s hot washing at 90°C or sterilization at 135°C, these tags are made to withstand industrial laundry demands.

2. Seamless Integration with RFID Systems

The UHF RFID technology embedded in the laundry tags allows for seamless integration with existing laundry management systems. Whether you are utilizing RFID readers for automated tracking or incorporating them into a more extensive inventory management system, these tags provide the necessary compatibility needed for streamlined operations. The reliable read range of up to 8 meters ensures accurate tracking, keeping your laundry inventory in check.

3. Enhanced Tracking and Management Capabilities

With RFID laundry tags, you are enabled to track every piece of laundry through every stage of the laundry process. Efficient identification and inventory tracking leads to actionable insights, improving overall inventory control. You can track the movement of each textile item, ensuring that they are returned to the correct individuals or locations promptly. This visibility is crucial for maintaining customer satisfaction in industries such as hospitality and healthcare.

4. Robust Chemical Resistance

Our fabric laundry tags are engineered to tolerate various chemicals typically used in industrial laundries. They can resist detergents, softeners, and bleach, including both oxygen and chlorine variants. This chemical resilience extends the lifetime of the tags and ensures reliable performance, even in the harshest laundering environments.

5. Multiple Tagging Options

Textile RFID laundry tags offer versatile tagging options. Customers can choose between sewing the tags directly into garments or using hot stamping adhesive for secure attachment. This adaptability allows for easy integration into existing textiles without disrupting their function or appearance.

Installation of Textile Fabric RFID Laundry Tags

Stitch Tagging: To be stitched into the hem of a textile. Stitch the laundry tag away from the folding lines.

Heat Sealing: To be heat-sealed directly on the textile at +200°C (392°F), for 12~14s.

In Pouch: To be stitched like a standard care label. Stitch the laundry tag away from the folding lines.

Benefits of RFID Laundry Management

Enhanced Operational Efficiency

Incorporating RFID tags into your laundry management processes vastly improves operational efficiency. Automated tracking systems eliminate the need for labor-intensive manual processes, reducing staff time and costs associated with item tracking. This allows employees to focus on core tasks that add value to the business, enhancing overall productivity.

Superior Asset Tracking

With RFID technology, you can track every piece of laundry through its entire lifecycle, from initial processing to return to service. This superior asset tracking capability helps prevent losses and ensures that all items are accounted for, especially important in high-volume environments like hospitals and hotels.

Conformance to Industry Standards

The RFID laundry tags are designed to meet stringent industry standards for durability and performance. Their robust design is suitable for high-demand environments, making them ideal for commercial applications. By choosing our textile RFID tags, you align your laundry operations with leading practices, ensuring your business remains competitive.

Customer Testimonials

“We have significantly cut down on lost linens since we implemented the RFID laundry tags. The tracking system has transformed our laundry management!” — Mary T., Facility Manager

“Not only do the RFID tags hold up during washes, but they have improved our turnaround times considerably.” — John D., Operations Director

Frequently Asked Questions (FAQs)

Q: How long can RFID laundry tags last?

A: Our RFID laundry tags have an estimated lifetime of 200 washing cycles or 3 years, depending on usage conditions.

Q: Can these tags withstand high temperatures?

A: Yes, these tags are designed to withstand washing temperatures up to 90°C, sterilization at 135°C, and pre-drying conditions, making them perfect for industrial laundries.

Q: Are the tags resistant to chemicals?

A: Absolutely. These tags are resistant to common laundry chemicals, including detergents, softeners, and bleach.

Conclusion