Optimizing Textile Batch Management with RFID Tag

RFID laundry tags are designed specifically for industries where hygiene and inventory control are crucial.

Linen washing is a crucial aspect of daily management in hotels. Before washing, linens typically need to be sorted by color, texture, brand, and other categories, which can take 2 to 8 people several hours to sort different linens into separate chutes. This process is quite time-consuming. However, with the advancement of Internet of Things (IoT) RFID technology, the application of RFID laundry tags can solve this problem.

RFID laundry tags are widely used in various linen washing processes due to their high-temperature and high-humidity resistance. Many laundry facilities and their clients have adopted RFID laundry tags to track and manage linens and assets, transforming the traditional manual record-keeping of washing processes into fully automated handling and documentation.

After sewing RFID tags onto textiles, users can easily track the number of linens in circulation, how many are processed daily, the number of washes, and more. This significantly reduces linen loss rates and enhances profitability for users. The process includes:

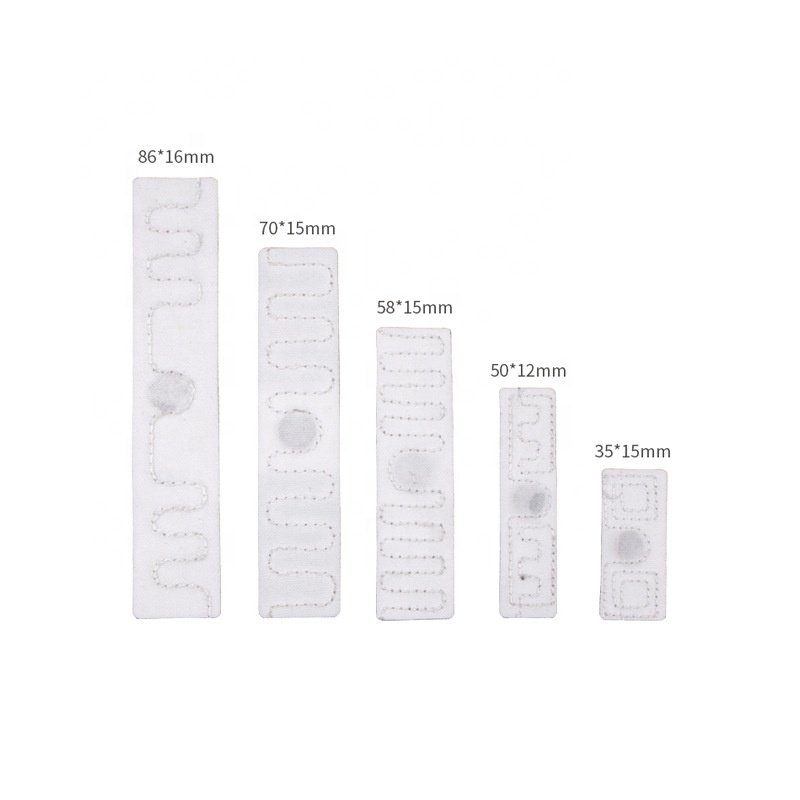

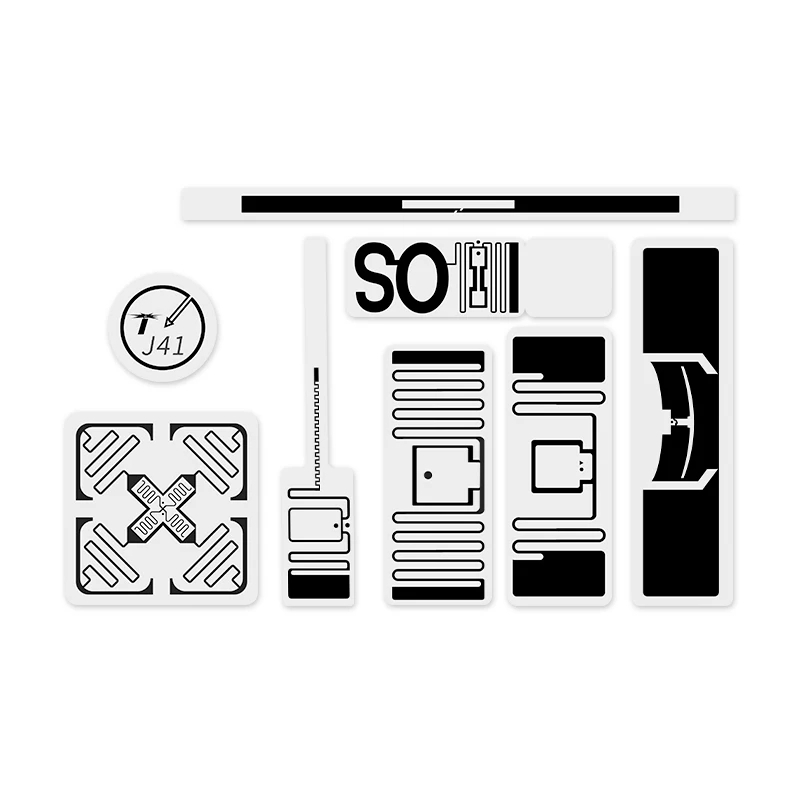

Ultra-high-frequency RFID laundry tags are widely utilized in the laundry industry due to their waterproof, moisture-resistant, ultra-high-frequency, high-temperature, and wash-resistant characteristics. They can be easily integrated into textiles (linens) through sewing or heat sealing. Each tag has a unique identification ID, ensuring high quality and reliability.

RFID technology brings a new transformation to the laundry industry. UHF RFID Laundry tags help identify and record cleaning times, cleaning requirements, customer information, and washing frequencies, reducing the error rate of traditional manual operations and significantly improving management efficiency.

RFID smart laundry solutions are driving the development of the laundry industry!

RFID (Radio Frequency Identification) technology uses electromagnetic fields to automatically identify and track tags attached to objects, allowing for efficient data collection and management.

By automating the tracking and management of linens, RFID tags reduce manual sorting time, minimize errors, and enhance overall operational efficiency.

Yes, RFID laundry tags can be reused multiple times as long as they are properly maintained and not damaged during the washing process.

RFID tags can be sewn or heat-sealed onto various textiles, including hotel linens, hospital garments, and industrial uniforms.

While RFID technology greatly enhances efficiency, it requires compatible reading and writing facilities, and proper installation is crucial to avoid damaging the tags.

Newest trends and common knowledge in RFID laundry tags.

RFID laundry tags are designed specifically for industries where hygiene and inventory control are crucial.

RFID labels are revolutionizing the way we track and manage inventory, assets, and even laundry.

Near Field Communication (NFC) technology has become a cornerstone in many industries, enabling quick and easy data transmission across various devices.

Didn’t find what you want? Ask our manager for help!