UHF RFID Laundry Tag for sorting and checking full automatic

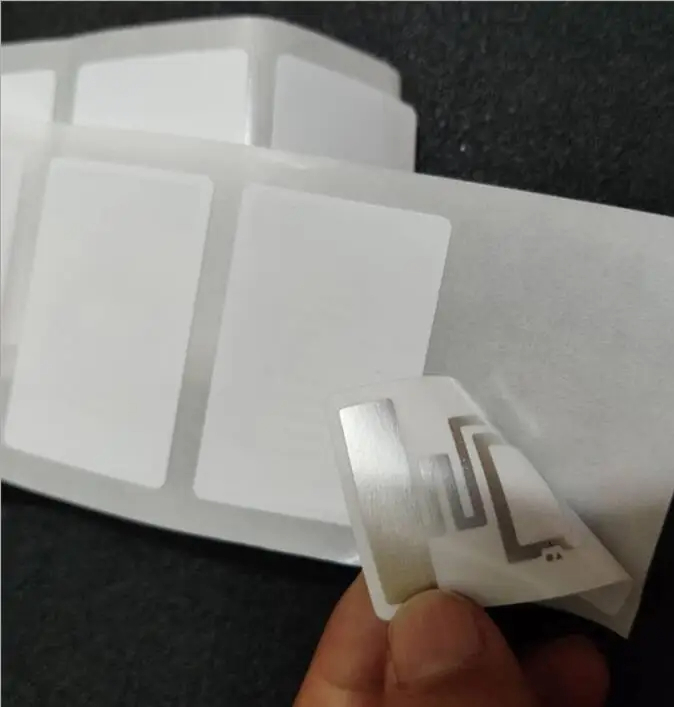

The UHF RFID Laundry Tag, utilizing the NXP UCODE 9 chip, represents a groundbreaking advancement in the automation of sorting and inventory management in laundry applications.

The management of uniforms and linens in various industries has become a critical aspect of operational efficiency. RFID (Radio Frequency Identification) laundry tags have emerged as a groundbreaking solution to simplify this process, providing businesses with a seamless way to track, manage, and maintain their garments effectively. With the benefits of durability, high-temperature resistance, and the ability to withstand industrial washing, RFID laundry tags offer an essential advantage for laundry management systems across industries such as hospitality, healthcare, and garment production.

Investing in RFID laundry tags means choosing a smarter, more efficient way to handle your uniform and linen inventory. These tags enable businesses to automate their processes, reduce labor costs, and significantly improve visibility into their garment lifecycle. With RFID technology, your organization can ensure that every piece of linen or uniform is accounted for, all while enjoying the benefits of real-time information and streamlined operations.

RFID laundry tags are engineered to withstand the rigorous demands of industrial washing environments. The textile tags boast a maximum operational temperature of up to 200°C, ensuring that they remain intact despite repeated laundering cycles. This durability allows businesses to track their uniforms and linens without the fear of RFID chips being damaged during high-heat processes.

With this level of reliability, you can trust that each RFID tag will perform consistently throughout its lifecycle, saving you from replacement costs and interruptions in your uniform service.

Implementing an RFID tracking system with laundry tags allows businesses to automatically monitor their inventory. By scanning tags with a handheld UHF reader, users gain immediate visibility into the quantity and condition of their garments.

With RFID laundry tags, you can improve your organization’s efficiency significantly, enhancing overall workflow in the laundry management process.

One of the standout features of using RFID laundry tags is the wealth of data they provide. By analyzing the data collected, businesses can make informed decisions about their garment needs and supplier relationships.

By leveraging this information, organizations can optimize their linen inventory and ensure that they maintain the highest standards in garment quality.

In addition to being robust and efficient, RFID tags are designed with environmental considerations in mind. Their long-lasting durability reduces waste associated with frequent replacements, and their efficient tracking leads to better inventory management, which also minimizes unnecessary purchases.

By utilizing RFID laundry tags, businesses can take a step towards sustainable practices while enhancing their operational capabilities.

RFID laundry tags are not limited to any single industry; they are versatile enough to be used in various applications, including:

RFID laundry tags can easily be integrated into your current laundry management systems. They are compatible with various platforms, enabling businesses to utilize existing workflows without significant changes.

A smooth transition to RFID laundry tags allows businesses to enhance their inventory management without significant disruptions.

Investing in RFID laundry tags is a strategic move for any organization looking to improve their uniform and garment management processes. Offering durability, ease of integration, and valuable data insights, these tags represent the future of laundry management. Don’t wait—contact us today to learn more about how RFID laundry tags can transform your uniform management program!

With RFID laundry tags, managing your garments and linens becomes effortless, efficient, and environmentally friendly. Adopt this cutting-edge technology and experience the difference it makes in streamlining your operations while ensuring the durability and functionality of your uniforms.

Newest trends and common knowledge in RFID laundry tags.

The UHF RFID Laundry Tag, utilizing the NXP UCODE 9 chip, represents a groundbreaking advancement in the automation of sorting and inventory management in laundry applications.

In today’s fast-paced world, technology is continuously evolving, enhancing convenience and efficiency in our daily lives. RFID tag utilizes electromagnetic fields to automatically identify and track tags attached to objects.

The 13.56 MHz RFID 1K token coin tags present an excellent solution for asset tracking, primarily due to straightforward installation, and robust durability.

Didn’t find what you want? Ask our manager for help!