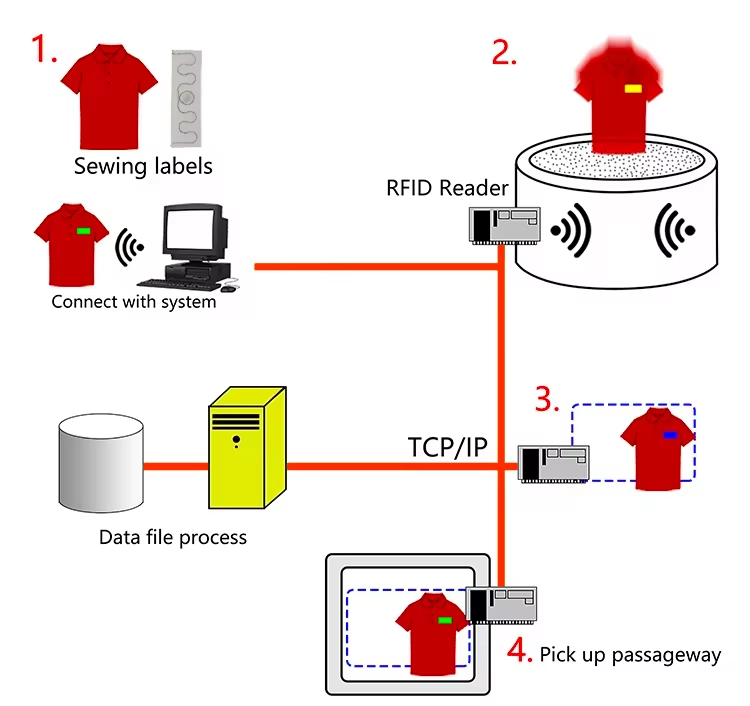

UNIQLO Global Stores Applied RFID Tags

UNIQLO upgraded its global stores with RFID tags, boosting efficiency and customer experience. This tech enhances inventory and streamlines sales, revolutionizing retail.

Efficient installation of RFID laundry tags is critical for ensuring accurate tracking, long-term durability, and smooth operation in industrial laundry environments. Whether you manage linens in hospitals, hotels, SPAs, cleaning services, retirement homes, or uniform rental companies, choosing the right installation method directly affects performance, read accuracy, and lifespan.

This guide explains the three main installation methods—heat sealing, sewn-in, and pocketing—while addressing frequent customer concerns such as tag durability, antenna protection, and washing resistance. We also introduce the UHF UCODE 9 Textile RFID Laundry Tag, engineered for high-temperature washing and long read performance.

Customers often worry about:

Tag failure after repeated washing or drying

Antenna damage during sewing

Tags falling off during industrial washing

Poor read performance caused by improper placement

Compatibility with different garment materials

By selecting the correct tag type and installation method, these challenges can be avoided—ensuring stable RFID performance for 200–300+ wash cycles.

Best for: Fast, secure installation on uniforms, linens, and high-volume laundry items.

Advantages

Extremely fast for mass production

Clean, professional appearance

Strong bond when installed correctly

How It Works

A heat-resistant RFID laundry tag with adhesive backing is pressed onto fabric using a heat-press machine. Heat and pressure activate the adhesive, bonding the tag securely to the textile.

Important Notes

Use tags designed for high-temperature exposure

Control heat and pressure to avoid damaging the chip

Not suitable for delicate fabrics

Best for: Heavy-duty use, long-term durability, items subjected to harsh washing.

Advantages

Strong attachment that withstands industrial washing

Economical installation method

Works with most textile materials

Outer Sewing:

Sew the tag directly onto the garment surface (using fabric labels). Stitch near the edge of the tag to avoid damaging the internal antenna.

Inner Sewing:

Place the tag inside the lining, hem, or a dedicated internal pocket for a discreet and more appealing look.

Key Notes

Always avoid the antenna area

Do not over-tighten the stitching

Suitable for repeated wash cycles

Best for: High-end textiles, hotel linens, sheets, or garments requiring hidden tags.

Advantages

Fully hidden installation

Maintains garment aesthetics and comfort

Tag can be replaced easily if needed

How It Works

A small pocket or opening is created in the garment. The RFID tag is inserted, then sealed with stitching or Velcro to keep it secure during washing.

Important Notes

Pocket must be properly sized

Ensure closure is tight to prevent tag from slipping out

Ideal for large linens that need discreet tracking

Choose industrial-grade laundry tags that are waterproof, heat-resistant, and chemical-resistant.

Avoid placing tags near metal parts such as zippers or buttons.

Select the tag type according to the textile: soft, woven, rigid, or flexible.

After installation, always test using an RFID reader to confirm stable performance.

A high-performance laundry tag engineered for demanding environments such as hospitals, hotels, uniforms, and linen service companies.

| Feature | Details |

|---|---|

| Product Name | UHF UCODE 9 Textile RFID Laundry Tag |

| Material | Textile / Fabric / Woven |

| Chip Model | NXP UCODE® 9 |

| Memory | EPC 96 bits |

| Protocol | EPC C1 G2 |

| Size Options | 70×15mm, 86×16mm, 50×20mm, 72×16mm, 35×15mm |

| Color | White |

| Durability | 200–300+ wash/dry cycles |

| Operating Temp. | -25℃ to +150℃ |

| Read Distance | 3–10 meters |

| Applications | Hotel linens, hospital laundry, industrial washing, uniforms, retail apparel management |

Glue backing for heat sealing

Encoding

Laser-printed numbers or logo

Ink printing

A Radio Frequency Identification laundry tag normally endures 200–300 wash and dry cycles, depending on water temperature, detergents, and installation quality.

No. Sewing is safe when stitches are placed along the outer edge of the tag and do not touch the antenna zone.

The pocketing or insert method is preferred for hotel linens because it hides the tag completely and maintains guest comfort.

Yes. Industrial-grade Radio Frequency Identification laundry tags are designed to tolerate high heat, steam, pressure, and strong detergents.

No. A properly installed Radio Frequency Identification laundry tag remains fully readable after tumble drying, steam finishing, or flatwork ironing.

A Radio Frequency Identification laundry tag generally provides a reading range of 3–10 meters, depending on the reader and environment.

Yes, but it should not be placed directly beside zippers, buttons, or other metal parts, which may block the signal.

The sewn-in method delivers the strongest attachment for workwear, uniforms, and textiles exposed to heavy mechanical friction.

Yes. Options include laser numbering, ink printing, logo printing, encoding, and adhesive backing for heat sealing.

Proper installation of Radio Frequency Identification laundry tags is essential for achieving stable reading performance, long-term durability, and reliable tracking in industrial laundry environments. Heat sealing offers fast and secure bonding, sewn-in installation provides the highest strength, and pocketing ensures a hidden and comfortable design. Choosing the right tag type, avoiding metal interference, and testing after installation are key to ensuring consistent performance through 200–300+ wash cycles.

Newest trends and common knowledge in RFID laundry tags.

UNIQLO upgraded its global stores with RFID tags, boosting efficiency and customer experience. This tech enhances inventory and streamlines sales, revolutionizing retail.

RFID (Radio Frequency Identification) technology is a contactless automatic identification system that utilizes radio frequency signals to identify and gather information without human intervention. This technology can quickly recognize fast-moving objects and can read multiple RFID tags simultaneously, making it efficient and convenient.

UHF RFID inlays offer long-range tracking and customization, enhancing efficiency and accuracy in logistics, inventory management, and asset tracking.

Didn’t find what you want? Ask our manager for help!