RFID Chips for Uniforms Garments and Linen Tracking Solution

RFID Chips for Uniforms, Garments, and Linen Tracking Solution represent a transformative advancement in laundry management. By investing in RFID laundry tags, businesses can enhance their operational efficiency, reduce losses, and improve overall inventory management.

Description

RFID Chips for Uniforms Garments and Linen Tracking Solution

RFID Chips for Uniforms, Garments, and Linen Tracking Solution offer businesses a robust way to manage their textiles, ensuring accuracy and reducing losses. This article dives deep into the benefits of using RFID laundry tags, how they work, and why they are a smart investment for any laundry operation.

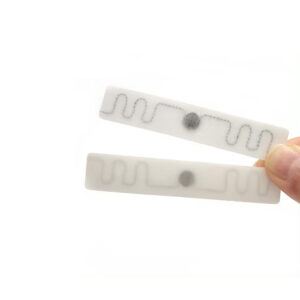

| Item Name: | RFID Chips for Uniforms Garments |

| RFID Standard: | ISO/IEC 18000-6 Type C (EPC Gen2) |

| Size&Weight: | 70×15 mm, 0.6g |

| Chip Type: | Impinj Monza 4QT,NXP U CODE 8,NXP U CODE 9 |

| EPC Memory: | 128bits |

| User Memory: | 512bits |

| Read Range(2W ERP FCC): | 8m |

| Read Range(2W ERP ETSI): | 8m |

| Tagging: | Sewing, Hot stamping adhesive |

| Estimated Lifetime: | 200 washing cycles or 3 years, whichever comes first |

| Washing Method: | Laundry, Dry cleaning |

| Water Extraction pressure: | 60 bar |

| Water Resistance: | Water resistant |

| Chemical Resistance: | Detergent, Softener, Bleach (Oxygen/ Chlorine), Alkali |

| Pre-drying in Tumbler: | 125 ºC for 15-20minute |

| Sterilization Temperature: | 135°C for 15-20minutes |

| Washing Temperature: | 90°C ,Up to 15min. |

| Humidity/ Temperature-Operating: | -20 to 110°C, 8 to 95%RH |

| Humidity/ Temperature-Storage: | -40 to 110°C, 8 to 95%RH |

Installation of RFID Chips for Uniforms Garments

Stitch Tagging: To be stitched into the hem of a textile. Stitch the laundry tag away from the folding lines.

Heat Sealing: To be heat-sealed directly on the textile at +200°C (392°F), for 12~14s.

In Pouch: To be stitched like a standard care label. Stitch the laundry tag away from the folding lines.

How STRONG they are ?

①.Are the RFID chips be damaged under high temperatures? –✔ Our RFID textile laundry tag are designed to be used at 200 °C.

②How many times can we wash the tags that are attached to uniforms textile products? –✔Our RFID textile laundry tag can be washed more than 200 times guaranteed for 2 years after shipping.

③Are we going to spend prestigious uniforms textile products, continue to work in case of chip crush? –✔We designed our textile laundry tag to withstand 60 bars of pressure in the process of pressing your textile products.

④Where do you place RFID textile laundry tags on uniforms textiles? – ✔RFID textile laundry tag are installed according to the availability of the uniforms.

What is RFID Laundry Tracking?

RFID (Radio Frequency Identification) laundry tracking is a technology that uses RFID tags attached to textiles to monitor and manage laundry items throughout their lifecycle. These tags, often referred to as RFID laundry tags, utilize radio waves to transmit data to RFID readers, allowing for real-time tracking and inventory management.This technology enhances laundry operations by automating the tracking process, ensuring that garments and linens are accounted for at every stage—from washing to delivery. By implementing an RFID laundry tracking system, businesses can significantly reduce human error and improve overall efficiency.

Benefits of RFID Laundry Tags

Enhanced Inventory Management

RFID laundry tags facilitate accurate inventory management by providing instant data on the location and status of every garment or linen item. This capacity enables laundry facilities to track items efficiently, ensuring that all uniforms and linens are available when needed, thus enhancing operational flow.

Reduced Loss and Theft

One of the significant advantages of using RFID tags in laundry operations is the reduction of loss and theft. Each tagged item can be easily identified and tracked, making it nearly impossible for items to go missing. Businesses can monitor their inventory in real-time, ensuring that everything is accounted for.

Improved Operational Efficiency

With RFID technology, laundry operations can automate various processes, leading to increased efficiency. Tasks such as sorting, tracking, and managing laundry can be streamlined, allowing staff to focus on more critical functions. This technology can also significantly reduce the time spent on manual inventory checks.

How Do RFID Tags Work?

The RFID System Components

An RFID system comprises three main components: RFID tags, RFID readers, and software for data management. RFID tags are attached to garments and linens, while readers scan and collect data from these tags. The collected data is then processed by management software for inventory tracking and reporting.

Data Transmission

When an RFID tag passes within the range of an RFID reader, the reader emits radio waves that power the tag, prompting it to transmit its unique identification number. This information is sent to the software, which logs the item’s location and status, allowing for real-time tracking.

Compatibility with Laundry Operations

RFID tags designed for laundry applications are durable and washable, ensuring they can withstand high-temperature wash cycles without losing functionality. They operate effectively even in harsh laundry environments, making them ideal for industrial laundry operations.

Key Features of RFID Laundry Tags

Washable and Durable

RFID laundry tags are engineered to be washable, allowing them to endure multiple wash cycles without degradation. They are constructed from durable materials that can withstand high temperatures and harsh detergents, ensuring long-lasting performance.

UHF Technology

Most RFID laundry tags utilize UHF (Ultra High Frequency) technology, which allows for a read range of several meters. This capability enhances tracking efficiency, enabling multiple items to be scanned simultaneously and without direct line-of-sight.

Customization Options

RFID laundry tags can be customized in various shapes, sizes, and memory capacities to suit specific operational needs. This flexibility allows businesses to choose tags that best fit their garment or linen management requirements.

Understanding UHF RFID Technology

What is UHF RFID?

UHF RFID operates within the frequency range of 300 MHz to 3 GHz, offering several advantages over other frequencies, including longer read ranges and faster data transmission rates. This technology is particularly beneficial for laundry applications, where tracking multiple items at once is essential.

Advantages of UHF RFID in Laundry Management

UHF RFID technology provides enhanced tracking capabilities, allowing for the efficient management of large inventories. Its ability to transmit data over longer distances means that laundry facilities can improve their workflow by minimizing the need for manual scanning.

Environmental Impact of RFID Laundry Tags

Sustainability Considerations

Implementing RFID technology in laundry operations can contribute to sustainability efforts. By reducing the loss of textiles and optimizing laundry processes, businesses can minimize waste and improve resource efficiency.

Lifecycle Impact

RFID laundry tags are designed for longevity, reducing the need for frequent replacements. Their durability ensures that they can withstand numerous wash cycles, significantly decreasing the environmental impact associated with textile waste.

Customer Reviews and Testimonials

Real-World Experiences

Many laundry facilities have reported significant improvements in efficiency and inventory accuracy after implementing RFID laundry tags. Customers appreciate the reduction in lost items and the ease of tracking their uniforms and linens.

“Since we adopted RFID laundry tracking, our operational efficiency has skyrocketed! We can now track our linens in real-time, which has greatly reduced our losses.” – Jane D., Laundry Manager

Positive Feedback

The feedback from users highlights the effectiveness and reliability of RFID laundry tags, making them a preferred choice among laundry services. Customers value the long-term savings associated with reduced inventory losses and improved management.

Frequently Asked Questions

How long do RFID laundry tags last?

RFID laundry tags are designed to endure up to 200 wash cycles, depending on the specific tag and washing conditions. Their durability ensures they remain functional throughout their lifecycle.

Can RFID laundry tags be customized?

Yes, RFID laundry tags can be customized in various shapes and memory capacities to meet the specific needs of your laundry operations.

What is the read range for UHF RFID tags?

UHF RFID tags typically have a read range of up to 6 meters, allowing for efficient tracking of multiple items simultaneously.

Conclusion

RFID Chips for Uniforms, Garments, and Linen Tracking Solution represent a transformative advancement in laundry management. By investing in RFID laundry tags, businesses can enhance their operational efficiency, reduce losses, and improve overall inventory management.