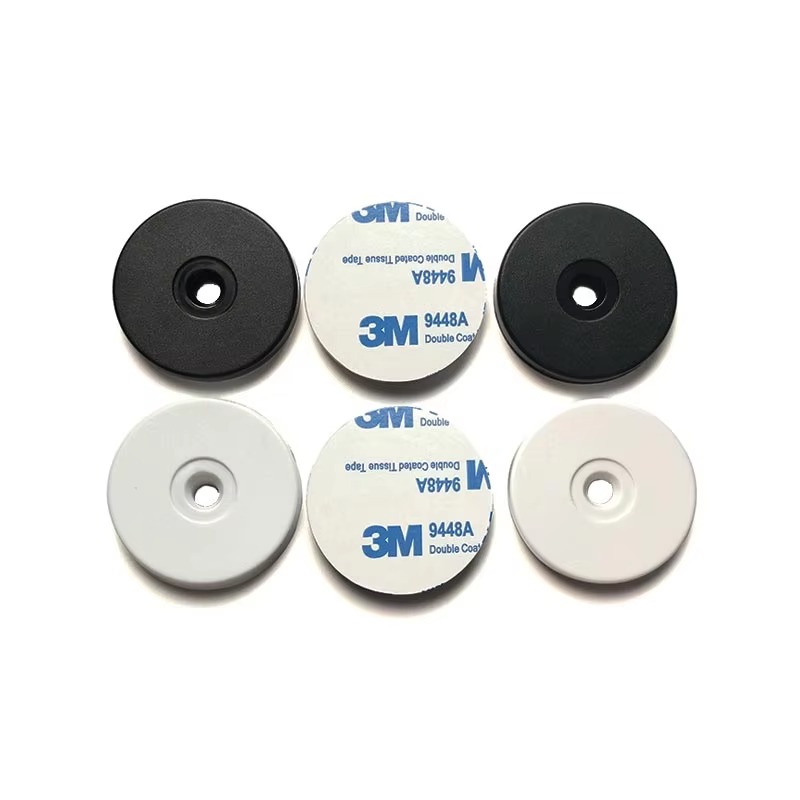

On-Metal NFC Screw Tag for Checkpoint Security

Enhance your operations with the On-Metal NFC Screw Tag. Durable, versatile, and equipped with NFC technology for seamless data transfer on metal surfaces.

Description

On-Metal NFC Screw Tag for Checkpoint Security: Ensure robust checkpoint security with our durable On-Metal NFC Screw Tag. Built with NTAG213 for reliable data transfer on metal surfaces, it seamlessly integrates into your security protocols, providing quick access and real-time tracking to enhance safety and efficiency.

Features of the On-Metal NFC Screw Tag

The On-Metal NFC Screw Tag is engineered with several notable features that make it a versatile solution:

- Durability: Constructed with an ABS shell that can withstand harsh environments, this tag is resistant to dust, water, and chemical corrosion, achieving an IP67 protection level.

- High Performance: The tag employs NTAG213 technology to facilitate fast read speeds, with data transfer rates of up to 106 kbit/s, allowing for efficient operations in busy environments.

- Anti-Metal Technology: The anti-metal function ensures that the tag operates effectively even when affixed to metallic surfaces, which would normally interfere with NFC signals.

These features render the On-Metal NFC Screw Tag ideal for applications in logistics, attendance control, and other industries where durability and performance are paramount.

Technical Specifications

| Specification | Details |

|---|---|

| Chip | NTAG213 |

| Memory | 144/504/888/1K bytes |

| Protocol | ISO 14443A |

| Frequency | 13.56MHz |

| Color Options | Black, White, Yellow |

| Diameter | 25/30/35/40/52 mm (custom sizes available) |

| Thickness | 5 mm |

| Weight | 3 g |

| Operating Temp | -25°C to 70°C |

| Erasability | > 100,000 erasures |

| Reading Distance | 2-20 cm (depending on environment) |

Armed with these capabilities, the On-Metal NFC Screw Tag stands as a powerful tool for various NFC applications.

Applications in Different Industries

The versatility of the On-Metal NFC Screw Tag allows it to be utilized across multiple sectors:

- Access Control: Easily manage entry points in secure locations by attaching NFC tags to doors or gates. The tags can be linked to user profiles for seamless authentication.

- Logistics and Inventory Management: Simplify the tracking of goods by placing tags on metal containers. The durability of these tags ensures they withstand the rigors of manufacturing and shipping.

- Public Transportation: Enhance user experience by employing On-Metal NFC tags for ticketing systems, allowing riders to check their status or recharge their accounts easily.

By implementing these tags, companies can streamline operations and significantly improve service delivery.

Advantages of Using NTAG213, NTAG215, and NTAG216

The NTAG213, NTAG215, and NTAG216 chips from NXP Semiconductors offer distinct advantages:

- Segmentation: Users can segment memory for multiple applications, making the tags flexible in functionality.

- Security Features: Equipped with ECC-based originality signatures and password protection, these tags safeguard data from unauthorized access and ensure integrity.

- High Capacity and Performance: The expanded memory options make it suitable for applications requiring significant data storage while maintaining fast read capabilities.

These advantages allow businesses to customize their solutions according to specific operational needs.

Installation and Usage Instructions

Installing the On-Metal NFC Screw Tag is straightforward:

- Select a Location: Choose a flat surface on the metal item where the tag will be placed. Ensure the surface is clean and dry.

- Secure with Screws: Use screws through the provided screw holes on the tag for a permanent fixture.

- Adhesive Option: Alternatively, the tag can be attached using a strong adhesive if preferred.

Once installed, the tags can be scanned easily with compatible NFC-enabled devices, allowing immediate access to information stored on the tag.

FAQs about On-Metal NFC Tags

Q: Can the On-Metal NFC Screw Tag work on all metal surfaces?

A: Yes, thanks to its specialized anti-metal technology, the tag operates effectively on various metallic surfaces without interference.

Q: How do I program or write data to the NTAG213 tag?

A: Programming can be accomplished using compatible NFC-enabled devices with the appropriate app. For more complex applications, consider using dedicated NFC writing software.

Q: What is the operational temperature range for these tags?

A: The tags function effectively in temperatures ranging from -25°C to 70°C.

Environmental Considerations

The On-Metal NFC Screw Tag is designed with sustainability in mind. Its robust construction minimizes the need for replacements, reducing waste. Moreover, when disposed of properly, the elements used in manufacturing these tags are recyclable.