Laundry RFID Tags TOP 5 Manufacturer

As a top global manufacturer, we specialize in Laundry RFID Tags, providing tailored solutions backed by 15 years of expertise and over 200 million tags delivered.

Laundry RFID tags represent a cutting-edge solution for tracking and managing textile assets throughout their lifecycle. These durable, flexible RFID transponders are crafted from fabric that can withstand heat, pressure, and stretching, making them ideal for monitoring items like workwear, uniforms, and flat linens. Equipped with a unique identifier, these RFID linen transponders facilitate touchless laundry management and enhance digital transparency. When integrated with IT management systems, RFID technology enables seamless tracking of textiles from soil collection to laundering and distribution.

|

Item

|

Laundry RFID Tags

|

|

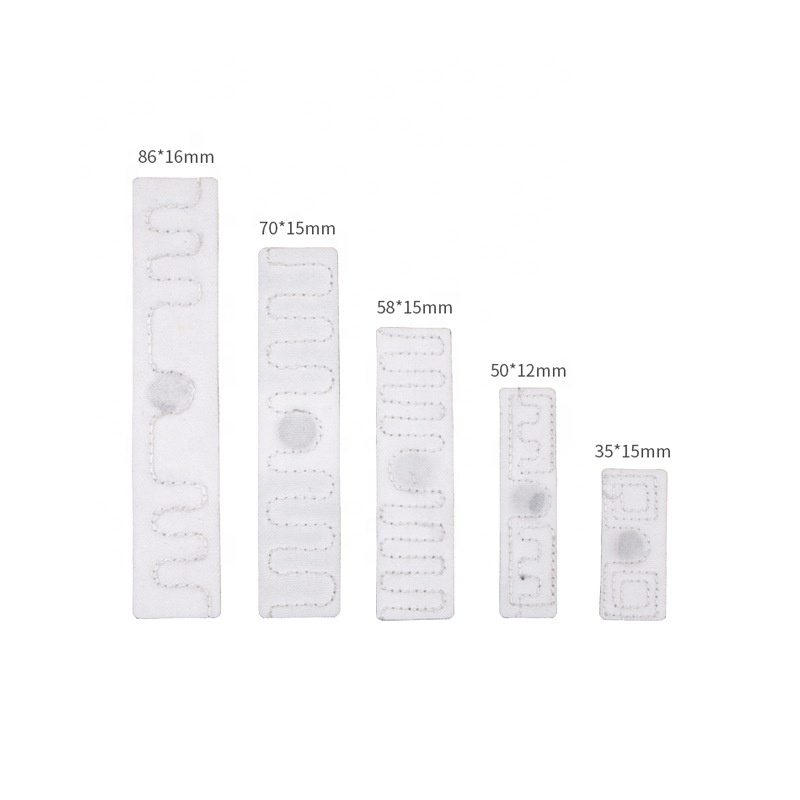

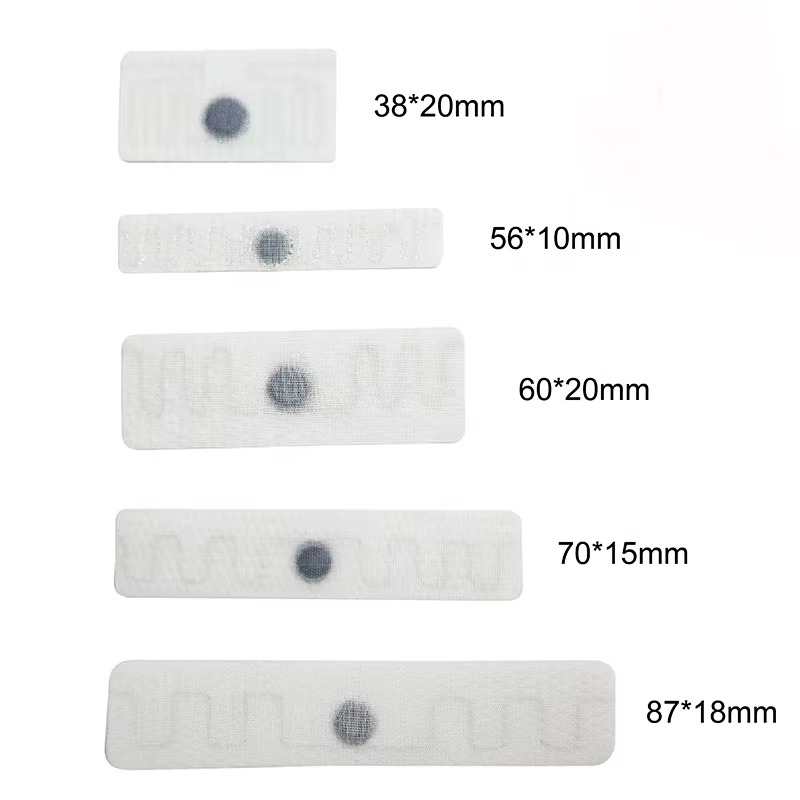

Size

|

55 X 12 mm,70 X 15 mm,87 X 17 mm

|

|

Operating Frequency

|

865-928 MHz

|

|

Tag Material

|

Polyester

|

|

Chips

|

U8, U9, etc

|

|

Tag Warranty

|

First of 200 or 300 wash cycles or 3 years from ship date

|

|

Read Distance

|

Up to 8 meters (up to 9 feet), have to test it with your reader

|

|

Storage Temperature

|

-40℃ to+120℃(-40℉ to +248℉)

|

|

lroner

|

+195℃(+383 F ) 30 seconds <18 bars

|

|

Water Extractor

|

60 bars,80 seconds

|

|

Autoclave

|

Air removal:+100C(+212F),5 minutes,0.1 bar,

|

|

Drying

|

+45℃(+113℉),.15 minutes,0.2 bar

|

|

Chemical Resistance

|

All Chemicals common to the washing process

|

Frequently Asked Questions (FAQ) of Laundry RFID Tags

Q1: What issues do Laundry RFID Tags address during the washing process?

A1: One major issue is that tags can easily be damaged, leading to data loss. Our solution utilizes industrial-grade polyester and high-temperature curing technology, allowing tags to withstand 195°C ironing and 60 Bar water pressure, perfectly suited for hotel linen sterilization processes. Our unique chemical-resistant coating protects against bleach and strong alkaline detergents, ensuring zero damage to the U8 chip over 300 washes, backed by 15 years of experience.

Q2: How do your tags improve sorting efficiency?

A2: Traditional tags often have short reading distances, which can hinder sorting efficiency. Our RFID technology offers an impressive 9-meter reading range, compared to the industry average of 5 meters. Coupled with directional antennas, this enhances batch scanning on laundry conveyer belts, improving sorting efficiency by 60%. Our tags also support a full frequency range of 865-928MHz and are compatible with leading RFID devices globally.

Q3: How do your tags reduce operational costs?

A3: Frequent tag replacements drive up operational costs. We offer a pioneering “3-year or 300 washes” dual warranty, reducing lifecycle costs by 42% compared to standard tags. Our modular chip design supports seamless upgrades from U8 to U9 versions, preventing the need for complete tag replacements due to equipment changes. Our tags have been certified through 2000 industrial wash tests, making them ideal for high-frequency turnover scenarios in linen rental businesses.

Factory Advantage: As a top 5 global manufacturer of Laundry RFID Tags with 15 years of RF technology expertise, we provide comprehensive solutions from chip packaging to scenario testing. We have delivered over 200 million specialized laundry tags to clients like Hilton and Mayo Clinic, supported by a professional team for customized development.

Variable Data for Laundry RFID Tags

Each laundry RFID tag is equipped with variable data, including:

- Laser Printed Information: This includes EPC codes, 1D and 2D barcodes, QR codes, and logos.

- RFID Chip Data Programming: Tags can be programmed with EPC encoding and locked with an access password.

- Comprehensive Testing: All data, including EPC encoding and TID, is 100% tested to ensure accurate matching for each specific tag.

Installation Methods

- Stitch Tagging: Ideal for stitching into the hem of textiles, ensuring that tags are placed away from folding lines for optimal durability.

- Heat Sealing: Tags can be heat-sealed directly onto textiles at +200°C (392°F) for 12 to 14 seconds.

- In Pouch: Similar to standard care labels, these tags can be stitched into a pouch, keeping them secure and easily accessible.

Applications of Laundry RFID Tags

Laundry RFID Tags are versatile and can be utilized across various industries for tracking textile assets, including:

- Healthcare: Monitoring linens, uniforms, masks, and mops.

- Hospitality: Managing flat linens and uniforms for hotels and restaurants.

- Fashion Apparel: Enhancing inventory management and tracking for clothing and accessories.

As the fashion and apparel industry evolves, the demand for advanced technology solutions grows. RFID technology has emerged as a vital tool for improving operational efficiency, enhancing customer experiences, and supporting sustainability initiatives. The implementation of laundry RFID tags in clothing and textile management has transformed how organizations oversee their laundry operations, enabling real-time tracking, improved inventory management, enhanced supply chain visibility, and greater sustainability.

By adopting these innovative solutions, businesses can streamline their processes and meet the increasing demands of a dynamic market.