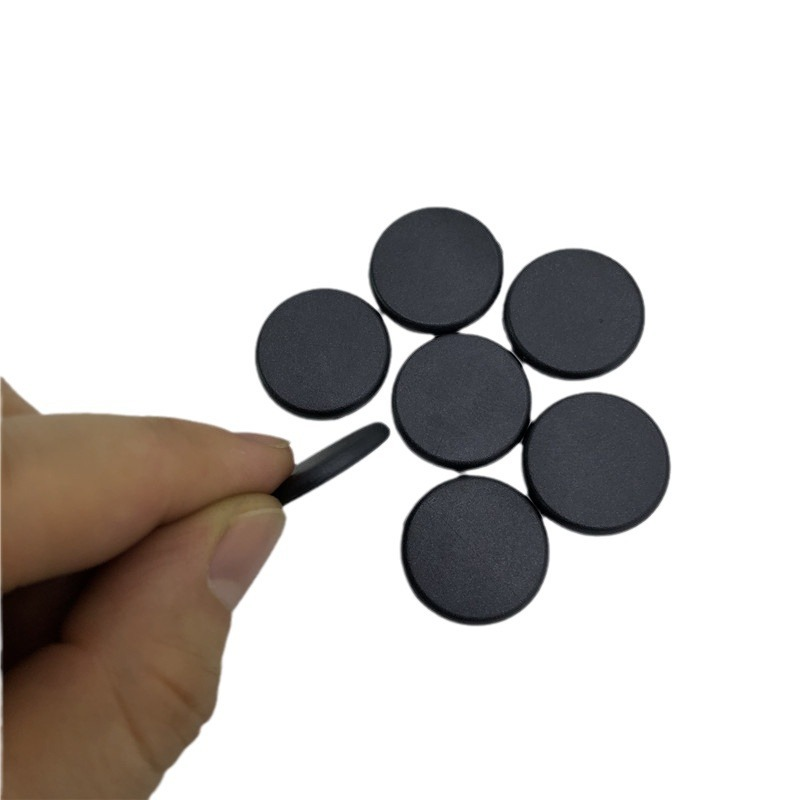

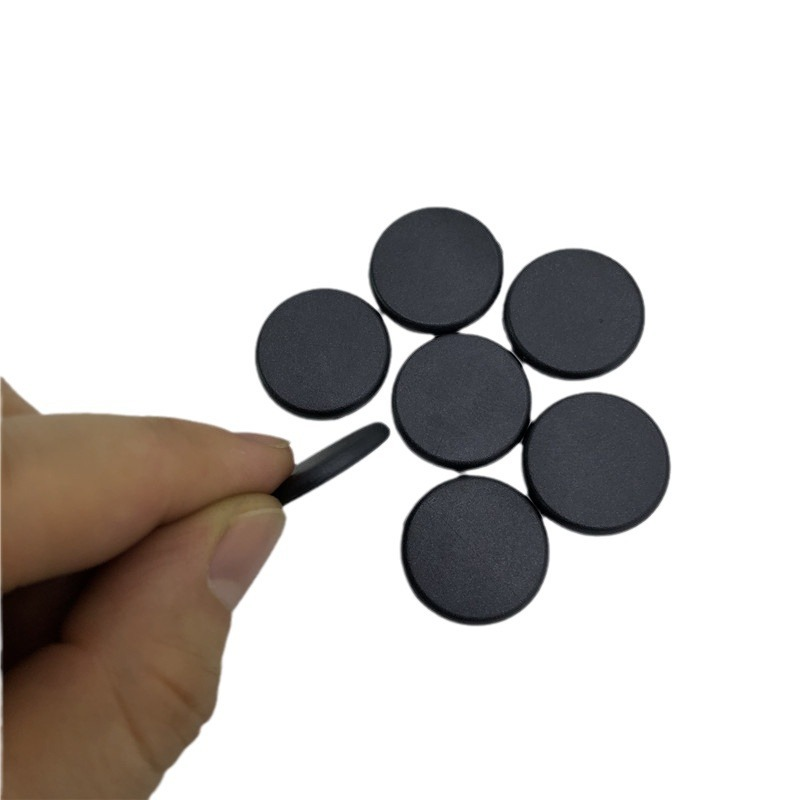

High-Temperature Resistant RFID Laundry Tags: Dia14mm

High-temperature resistant RFID laundry tag, designed for various applications in the laundry and clothing industry.

A Practical Guide for Hotels, Hospitals, and Industrial Laundries

With the rapid adoption of RFID technology in laundry and linen management, more hotels, hospitals, and uniform service providers are embedding RFID washable laundry tags into each textile item. By sewing an RFID laundry tag into every piece of linen or garment, businesses can automatically track usage status, washing cycles, inventory movement, and handover records throughout the entire lifecycle of the textile.

Using RFID readers, hundreds of items can be scanned simultaneously during washing, sorting, and delivery. This not only simplifies handover processes and improves transparency, but also reduces disputes, prevents losses, and increases operational efficiency. Most importantly, by analyzing wash count data, RFID systems help predict linen lifespan and support data-driven procurement planning.

However, many customers share the same concerns:

Will sewing damage the RFID chip? Where should the tag be installed? Will it affect reading performance or fabric comfort?

This guide explains how to correctly sew RFID laundry tags into linens, step by step, while avoiding common mistakes.

Incorrect installation can lead to:

Reduced read range or unstable RFID performance

Physical damage to the chip during washing or ironing

Shortened tag lifespan

Increased replacement costs

Correct sewing ensures stable performance over 200–300+ industrial wash cycles, even under high temperature, high pressure, and chemical exposure.

This is one of the most common and cost-effective methods.

Best practices:

Use strip-shaped RFID laundry tags

Sew the tag into the hem or folded edge of the linen or garment

Choose a fixed, standardized location for all items to improve scanning efficiency

Key sewing guidelines:

Leave at least 0.5 cm of space at both ends of the RFID tag

Stitch only at the two ends of the tag, never across the center

Do not sew through the antenna or chip module

Ensure the tag is positioned away from folding lines

This method protects both the chip and sewing equipment while maintaining optimal RFID performance.

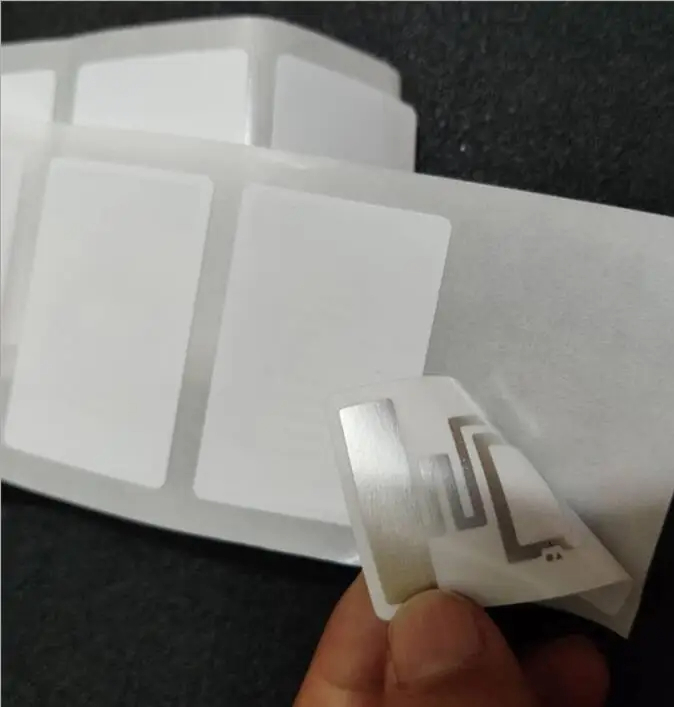

For customers who want extra protection or easier replacement, a fabric pouch is recommended.

How it works:

The RFID laundry tag is placed inside a textile pouch (commonly 70 × 15 mm, customizable)

The pouch is sewn securely around its edges

The pouch is installed under the hem or near the edge, not on fold lines

Advantages:

Enhanced mechanical protection

Reduced risk of needle damage during sewing

Ideal for heavy-duty hospital and industrial laundry applications

Important note:

Stitch around the pouch, never across the chip or antenna area.

Install tags near the edge or corner

Keep tags away from folding lines

Avoid areas exposed to repeated stress or tight folding

The same principles apply, but additional evaluation is recommended

Coordinate with:

Textile suppliers

Laundry service providers

End users

Special attention should be paid to sorting conveyors, tunnel washers, and inbound/outbound scanning points to ensure smooth system operation.

Sewing directly through the chip module

Stitching across the antenna area

Placing tags on frequent fold lines

Installing tags at random, inconsistent positions

Using overly tight stitches that stress the tag during washing

Avoiding these mistakes significantly improves read accuracy and tag durability.

✔ Stable bulk reading during washing and sorting

✔ Accurate tracking of wash cycles and usage history

✔ Reduced linen loss and labor costs

✔ Transparent handover and fewer disputes

✔ Predictable textile lifespan and smarter purchasing decisions

Yes. High-quality RFID laundry tags are designed to withstand high temperatures (up to 200°C ironing), high pressure, and chemical detergents used in industrial laundries.

Not if done correctly. As long as the stitching avoids the chip module and antenna area, RFID performance will not be affected.

Near the edge or corner of the textile, away from folding lines. A fixed, consistent position improves scanning efficiency.

A pouch is optional but recommended for heavy-duty applications, such as hospitals or industrial laundries, where textiles undergo frequent and harsh washing cycles.

Yes. One of the biggest advantages of RFID is simultaneous bulk reading, enabling fast sorting, counting, and handover verification.

Depending on tag quality and washing conditions, most RFID laundry tags last 200–300+ industrial wash cycles, and often match or exceed the textile’s lifespan.

Newest trends and common knowledge in RFID laundry tags.

High-temperature resistant RFID laundry tag, designed for various applications in the laundry and clothing industry.

In today’s fast-paced world, technology is continuously evolving, enhancing convenience and efficiency in our daily lives. RFID tag utilizes electromagnetic fields to automatically identify and track tags attached to objects.

Near Field Communication (NFC) technology has become a cornerstone in many industries, enabling quick and easy data transmission across various devices.

Didn’t find what you want? Ask our manager for help!