How to Choose RFID Laundry Tags?

Choosing the right RFID laundry tags can significantly enhance the efficiency of your laundry operations. This article delves into the essential factors to consider when selecting RFID tags, ensuring you make an informed decision that meets your specific needs. Whether you’re managing a large laundry facility or a small business, understanding the nuances of RFID technology will help you streamline your processes and improve tracking capabilities.

Article Outline

- What are RFID Laundry Tags?

- How Do RFID Laundry Tags Work?

- What Applications Benefit from RFID Laundry Tags?

- How to Choose Custom RFID Laundry Tags?

- What is the Importance of Reliable RFID Tags?

- How Do Textile RFID Tags Differ from Standard RFID Tags?

- What are the Key Features of UHF RFID Laundry Tags?

- How to Ensure Proper Identification with RFID Tags?

- What are the Cost Considerations for RFID Laundry Tags?

- How to Implement RFID Laundry Tags Effectively?

What are RFID Laundry Tags?

RFID laundry tags are specialized tags designed to track and manage textiles in laundry operations. These tags utilize radio frequency identification (RFID) technology to provide real-time data on the location and status of items. By embedding RFID tags into textiles, businesses can automate inventory management, reduce losses, and enhance operational efficiency.

The primary advantage of RFID laundry tags is their ability to provide accurate tracking without the need for manual scanning. This technology allows for quick identification of items, making it easier to manage large volumes of laundry. As a result, businesses can save time and reduce labor costs, ultimately leading to increased profitability.

How Do RFID Laundry Tags Work?

RFID laundry tags operate using a system of readers and tags. Each tag contains a microchip and an antenna, which communicate with RFID readers. When an RFID reader emits a radio signal, the tag responds by transmitting its unique identification number. This process allows for the automatic identification and tracking of items.

The technology behind RFID tags can be classified into two main types: passive and active. Passive RFID tags do not have a power source and rely on the reader’s signal to operate, while active RFID tags have their own power source and can transmit signals over longer distances. For laundry applications, passive UHF RFID tags are commonly used due to their cost-effectiveness and efficiency.

What Applications Benefit from RFID Laundry Tags?

RFID laundry tags are versatile and can be applied in various industries, including hospitality, healthcare, and industrial laundry services. In the hospitality sector, hotels use RFID tags to track linens and towels, ensuring that items are returned to the correct rooms. In healthcare, RFID tags help manage hospital gowns and bed linens, reducing the risk of cross-contamination.

Moreover, industrial laundry services benefit from RFID technology by streamlining their operations. By implementing RFID laundry tags, businesses can automate inventory management, track items throughout the cleaning process, and reduce losses due to misplaced or unreturned items.

How to Choose Custom RFID Laundry Tags?

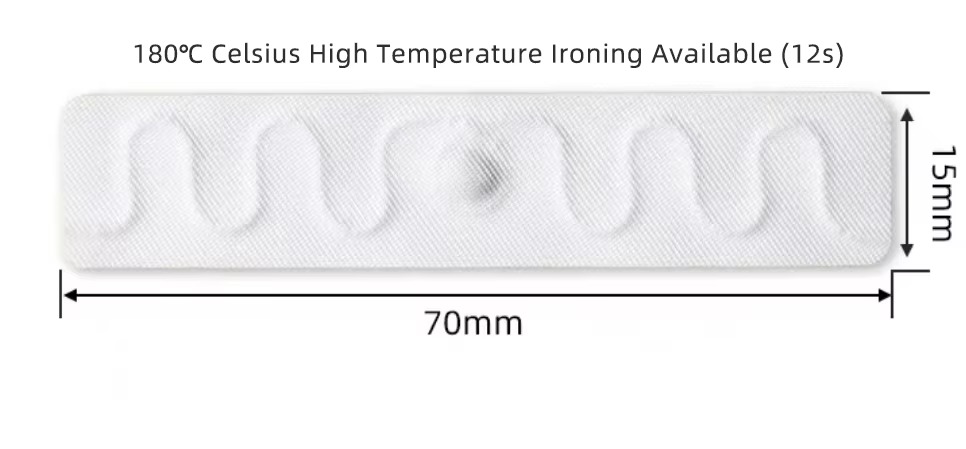

When selecting custom RFID laundry tags, consider factors such as material, size, and durability. The material of the tag should be compatible with the textiles it will be attached to, ensuring that it can withstand the laundry process. Additionally, the size of the tag should be appropriate for the item it will be attached to, allowing for easy scanning without compromising the item’s appearance.

Customization options also include printing logos or barcodes on the tags, which can enhance brand visibility and provide additional tracking capabilities. It’s essential to work with a reputable supplier who can provide guidance on the best options for your specific needs.

What is the Importance of Reliable RFID Tags?

Reliability is a crucial factor when choosing RFID laundry tags. Tags that fail to function correctly can lead to inaccurate tracking and inventory management issues. To ensure reliability, select tags that are tested for durability and performance in various laundry conditions, including high temperatures and exposure to chemicals.

Additionally, consider the read range of the RFID tags. Tags with a longer read range can improve efficiency by allowing for quicker scanning of multiple items at once. Investing in reliable RFID tags will ultimately save time and reduce operational costs.

How Do Textile RFID Tags Differ from Standard RFID Tags?

Textile RFID tags are specifically designed for use in laundry applications, differentiating them from standard RFID tags. These tags are made from materials that can withstand the rigors of the laundry process, including high temperatures and moisture. Textile RFID tags are often sewn or embedded into garments, ensuring they remain securely attached during washing and drying.

Furthermore, textile RFID tags are designed to be lightweight and flexible, minimizing their impact on the comfort and appearance of the items they are attached to. This is particularly important in industries such as hospitality and healthcare, where the aesthetics of linens and uniforms are essential.

What are the Key Features of UHF RFID Laundry Tags?

UHF (Ultra High Frequency) RFID laundry tags offer several advantages over other types of RFID tags. One of the key features of UHF tags is their longer read range, which can extend up to several meters. This allows for efficient scanning of multiple items at once, making them ideal for high-volume laundry operations.

Additionally, UHF RFID tags are known for their fast read speeds, enabling quick identification of items as they pass through the laundry process. This efficiency can significantly reduce the time spent on inventory management and tracking, ultimately improving overall operational efficiency.

How to Ensure Proper Identification with RFID Tags?

Proper identification is essential for effective inventory management using RFID laundry tags. To ensure accurate identification, it’s crucial to implement a robust tagging system that includes unique identifiers for each item. This can be achieved by assigning a specific RFID tag to each piece of laundry, allowing for precise tracking throughout the cleaning process.

Regular audits and maintenance of the RFID system are also necessary to ensure that tags remain functional and accurately reflect the status of items. By prioritizing proper identification, businesses can minimize losses and improve overall efficiency.

What are the Cost Considerations for RFID Laundry Tags?

When evaluating the cost of RFID laundry tags, consider both the initial investment and the long-term savings. While the upfront cost of RFID tags may be higher than traditional tracking methods, the potential for increased efficiency and reduced labor costs can lead to significant savings over time.

Additionally, consider the total cost of ownership, which includes maintenance, software, and hardware costs associated with implementing an RFID system. By conducting a thorough cost analysis, businesses can make informed decisions about the best RFID solutions for their needs.

How to Implement RFID Laundry Tags Effectively?

Implementing RFID laundry tags requires careful planning and execution. Start by assessing your current laundry processes and identifying areas where RFID technology can improve efficiency. Next, select the appropriate RFID tags and readers that align with your operational needs.

Training staff on how to use the RFID system is also crucial for successful implementation. Ensure that employees understand the benefits of RFID technology and how to operate the equipment effectively. By taking these steps, businesses can maximize the benefits of RFID laundry tags and streamline their operations.

Summary of Key Points

- RFID laundry tags enhance tracking and management of textiles.

- Customization options are available for RFID tags to meet specific needs.

- Reliability and durability are crucial