How RFID Laundry Tags Improve Linen Tracking Efficiency and Cut Costs

Table of Contents

How do RFID tags working for linen inventory management?

RFID Linen Management: Transforming Efficiency and Reducing Costs

Challenges in Traditional Linen Management

Traditional linen management often struggles with:

High labor costs: Manual counting and recording require dedicated staff, making the process time-consuming and error-prone.

Delayed inventory updates: Manual data entry causes slow information flow, making real-time monitoring impossible.

Unclear loss tracking: Linen losses and damages are hard to trace, resulting in inaccurate cost allocation.

Low washing efficiency: Lack of accurate linen allocation leads to redundant transport or supply shortages.

How RFID Technology Empowers Linen Management

An RFID laundry tag, composed of a chip and antenna, communicates with readers via wireless signals to deliver unmatched automation and accuracy.

Non-contact batch reading: Identify hundreds of linens in one scan, boosting efficiency by over 90%.

Unique digital identity: Each linen item has a unique RFID code for full lifecycle traceability.

High durability: Special PPS encapsulation ensures stable operation through 100,000+ industrial wash cycles.

Real-time tracking: UHF RFID tags allow accurate reading within 5 meters, with 99.9% accuracy.

Automated inventory updates: Integrated RFID systems automatically record linen movement, cutting labor costs by up to 50%.

Lifecycle monitoring: Track wash counts and wear to predict replacement cycles, extending linen lifespan and reducing waste.

Key Steps for RFID Linen Management Implementation

Demand Analysis & Solution Design

Define linen categories, quantities, and goals (e.g., 20% loss reduction). Select a suitable UHF RFID tag for high-speed batch reading.Hardware Deployment & Tag Installation

Embed heat-resistant RFID laundry tags during sewing or printing.

Install RFID readers at warehouses, transport vehicles, and laundry facilities.Software Integration

Connect to ERP or laundry management systems for real-time dashboards, inventory alerts, and cost analytics.Employee Training & Continuous Optimization

Create standardized operation manuals, test ROI through pilot runs, and scale across all departments.

Long-Term Value of RFID Linen Tracking

Cost Reduction: Save 15–30% in linen procurement and inventory labor costs.

Efficiency Boost: Reduce inventory checks from days to minutes.

Sustainability: Extend linen lifespan and align with ESG initiatives.

Customer Satisfaction: Ensure on-time linen supply and enhance brand reputation.

How to Use RFID Laundry Tags

Tagging: Sew or attach an RFID laundry tag to each garment or linen.

Scanning: Use handheld or fixed RFID readers during each process stage.

Tracking: Monitor location, washing cycles, and condition through integrated software.

Technical Specifications

| Item Name | RFID Laundry Tags for Uniforms |

|---|---|

| RFID Standard | ISO/IEC 18000-6C (EPC Gen2) |

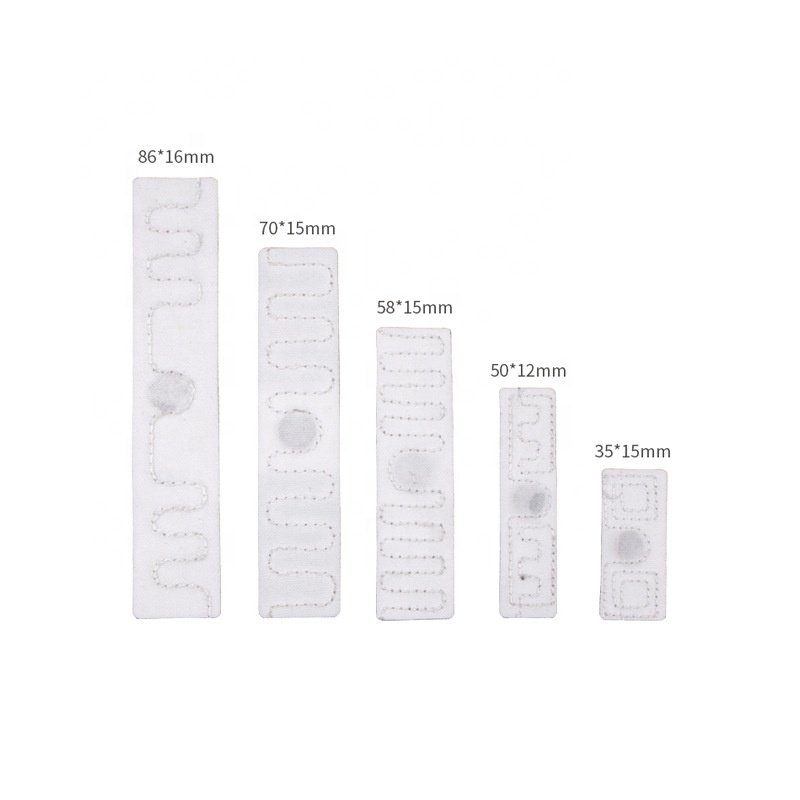

| Size / Weight | 70×15 mm / 0.6 g |

| Chip Type | NXP UCODE 8/9 |

| EPC Memory | 128 bits |

| User Memory | 512 bits |

| Read Range (2W ERP) | 8 m (FCC/ETSI) |

| Attachment | Sewing, Heat adhesive |

| Lifetime | 200 wash cycles / 3 years |

| Water & Chemical Resistance | Detergent, Softener, Bleach, Alkali |

| Temperature Resistance | Up to 135°C (sterilization), 90°C washing |

| Environment | -40°C to 110°C, 8–95% RH |

Get Customized RFID Laundry Tags

Upgrade your linen management system with custom RFID solutions designed for hotels, hospitals, and industrial laundries.

📩 Contact us to learn more about RFID tags for linen tracking and laundry management.