RFID Laundry Tags for Uniform Management: The Ultimate Solution for Garment Tracking

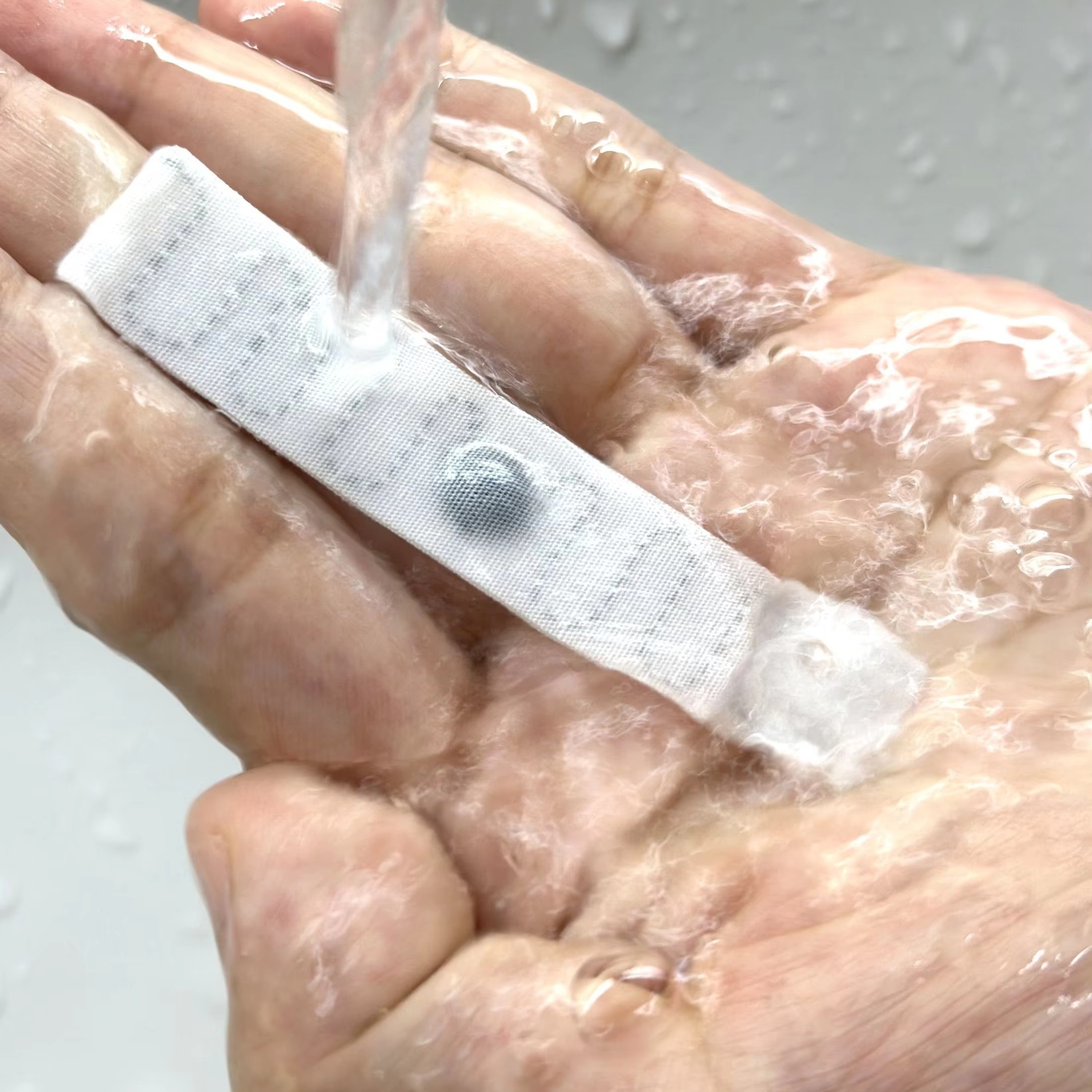

RFID laundry tags offer durable, high-temperature resistance for efficient tracking of uniforms and linens, enhancing visibility and reducing costs in various industries.